Kobelco Oil-Free Rotary Screw Air Compressor AC-8202

Kobelco Oil-Free Rotary Screw Air Compressor AC-8202

Contact us for price

Location:Ohio

or

Call 305-428-2777

Description

Overview

This Kobelco KNW Series is a premium oil-free, two-stage rotary screw air compressor designed for critical air applications requiring 100% oil-free compressed air. This industrial-grade unit features advanced control systems and delivers reliable, contamination-free compressed air for sensitive industrial processes. Located in Room 1, this is the second Kobelco KNW unit in the facility.

Design and Performance

- Manufacturer: Kobelco / Quincy (Rogers Machinery Co. Inc.)

- Model: AC-8202 (KNW Series)

- Type: Oil-Free Two-Stage Rotary Screw

- Control System: Graphic Touch Screen HMI Terminal

- Construction: Heavy-duty blue enclosure with integrated piping

Key Specifications

Condition

- Used - Commercial Grade

- Professional installation with copper piping connections

Performance Features

- 100% Oil-Free Air (Class 0)

- Two-Stage Compression

- Industrial-grade reliability

- Integrated moisture management

Control System

- Advanced HMI Touch Screen Interface

- LED status indicators (Run, Load, Alert, Alarm, Warning)

- Digital monitoring and diagnostics

- Remote monitoring capability

- Start/Stop/Reset functionality

Electrical (Based on Baldor Motor Specifications)

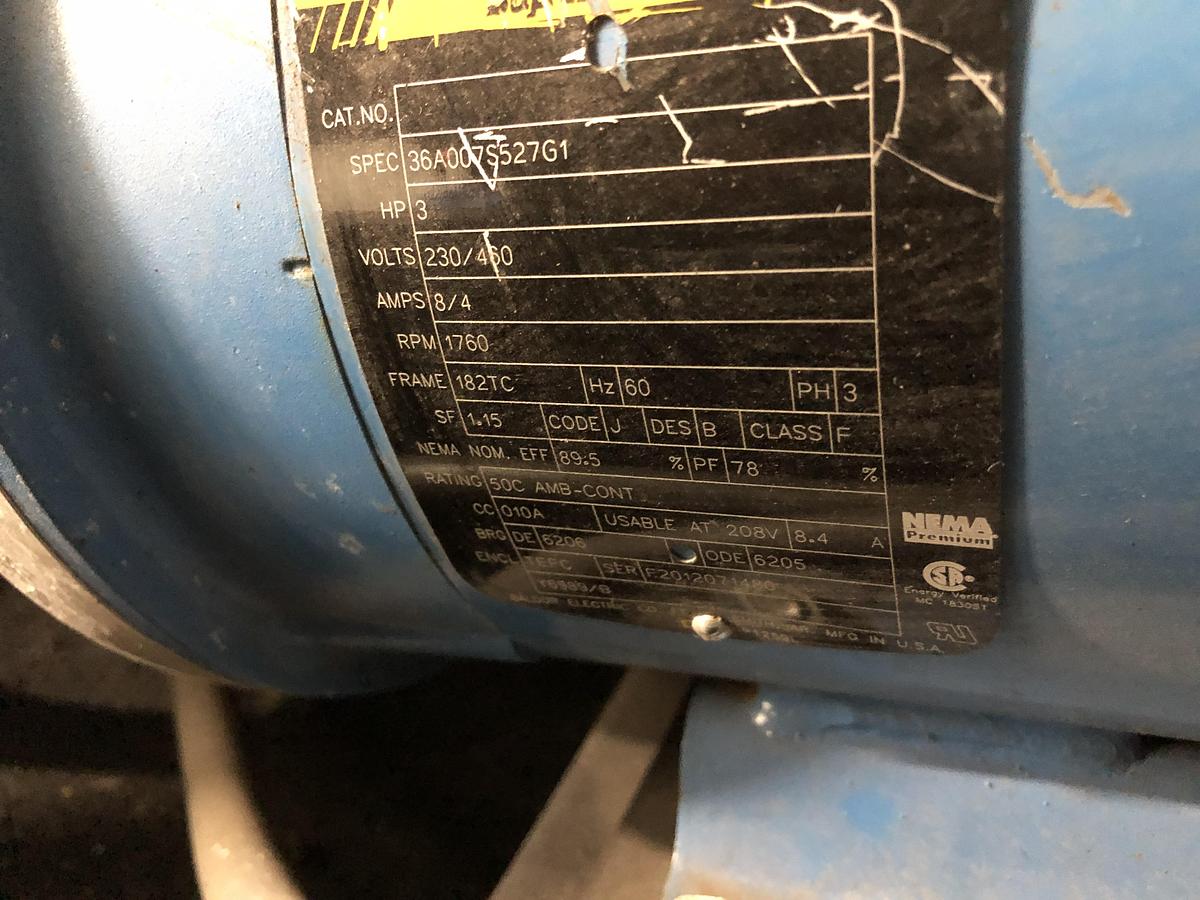

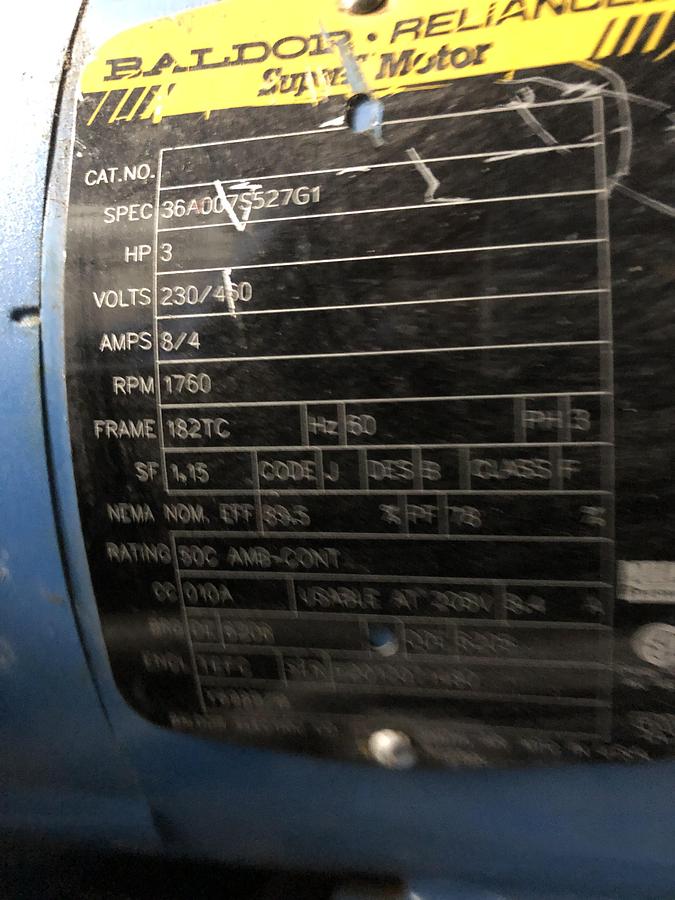

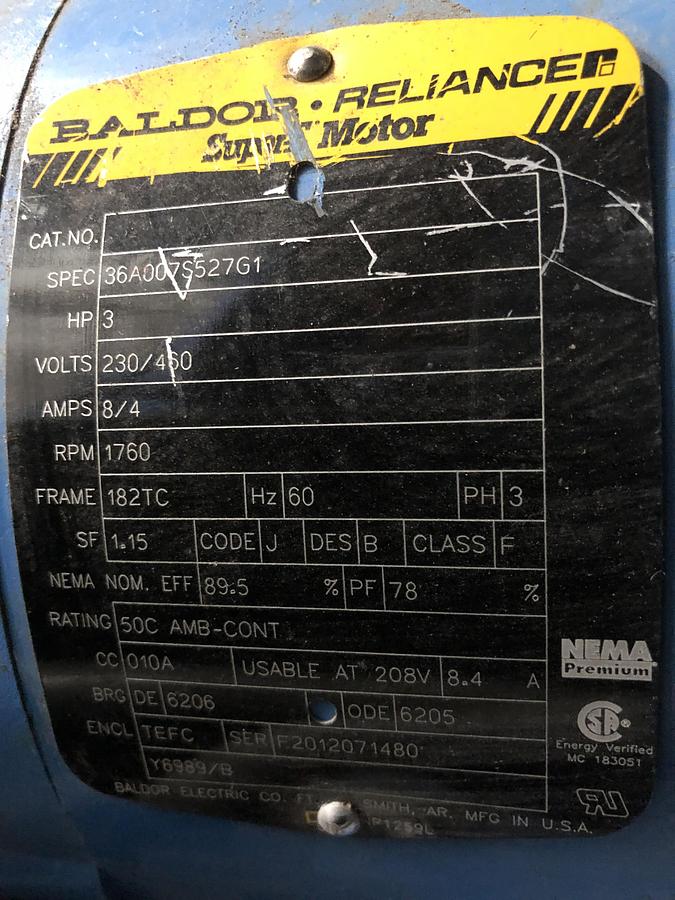

- Motor: Baldor Reliance Super E Motor

- Power: 3 HP

- Voltage: 230/460V

- Amperage: 8/4 AMP

- RPM: 1760

- Frame: 182TC

- Frequency: 60 Hz

- Phase: 3

- Service Factor: 1.15

- Efficiency: 89.5%

- Power Factor: 78%

- NEMA Design: B

- Insulation Class: F

- Ambient Temperature Rating: 50°C Continuous

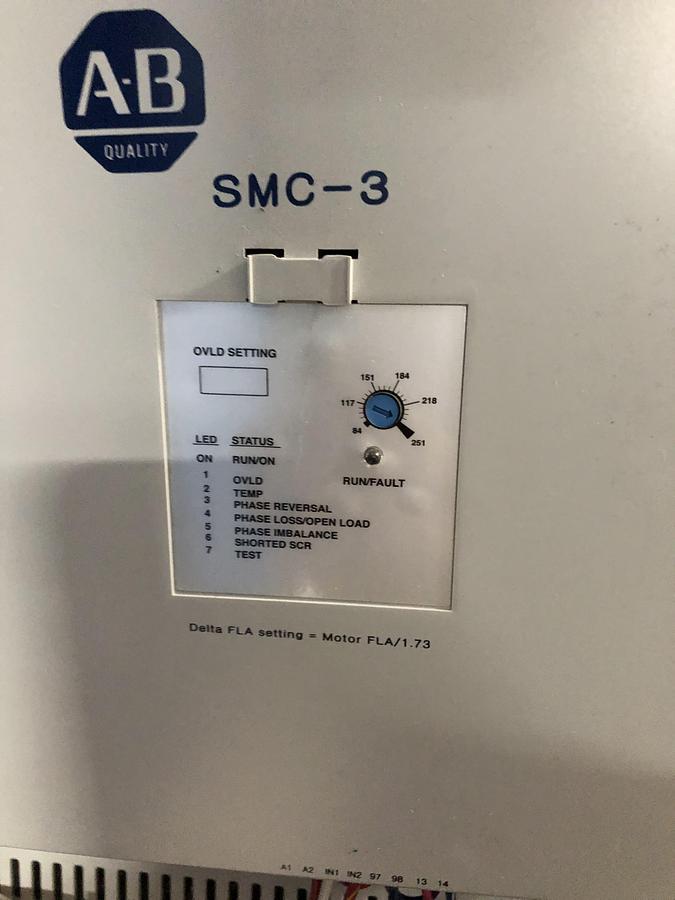

Motor Protection and Control

Allen-Bradley SMC-3 Features

- Overload (OVLD) Setting with dial adjustment

- LED Status Indicators:

- ON/RUN

- OVLD (Overload)

- Temperature

- Phase Reversal

- Phase Loss/Open Load

- Phase Imbalance

- Shorted SCR

- Test Mode

- Delta FLA Setting = Motor FLA/1.73

- Full motor protection capabilities

System Components

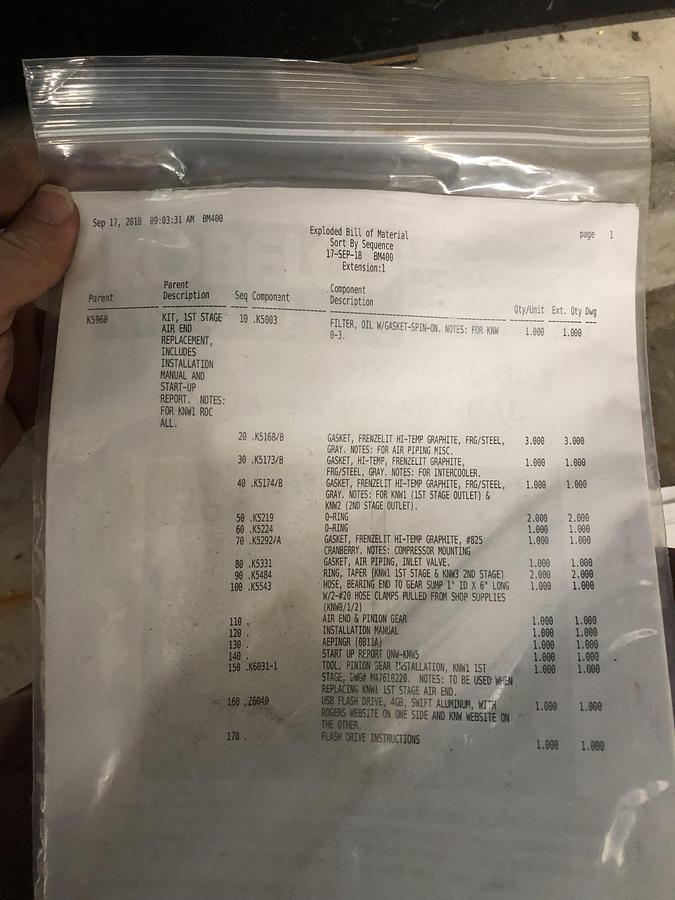

Compressor Package Includes

- Two-stage oil-free airend

- Baldor drive motor

- Integrated control panel with HMI

- Sound attenuated enclosure

- Inlet air filter system

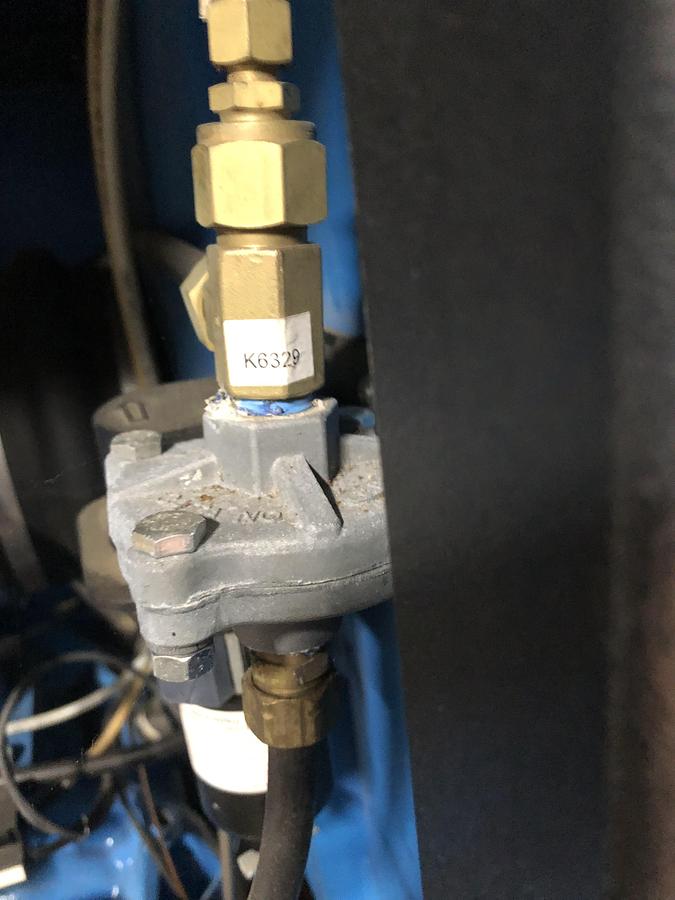

- Discharge piping with isolation valves

- Safety relief valves

- Professional-grade copper piping installations

Control Features

- Graphic touch screen interface

- Multiple operational buttons (Run, Load, Alert, Alarm, Warning)

- Run/fault diagnostics

- Programmable operation modes

- Service interval tracking

- System status monitoring

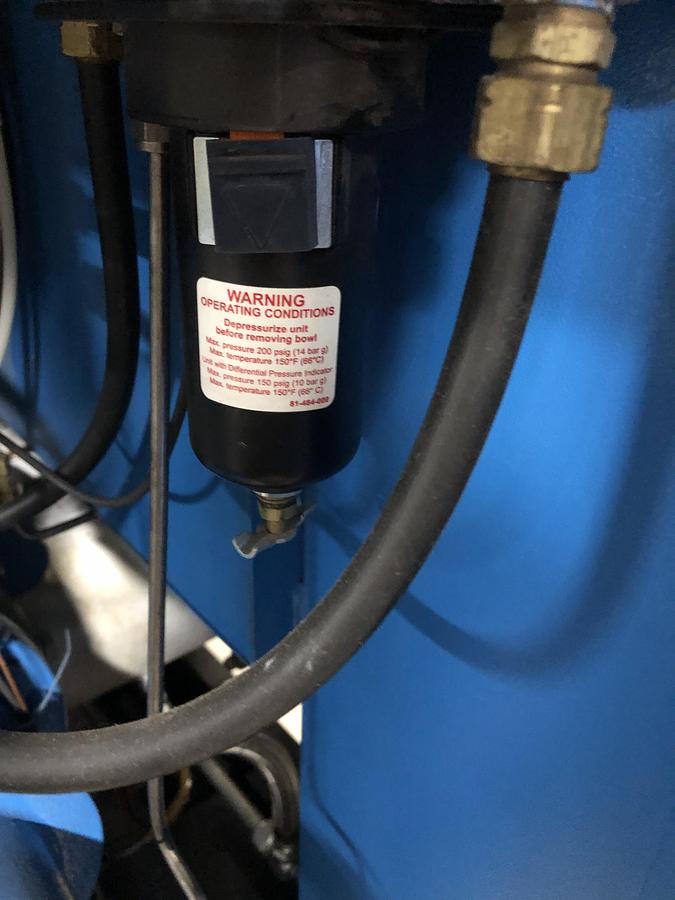

Safety Features

- Multiple safety interlocks via SMC-3 controller

- Overpressure protection

- Temperature monitoring

- Phase reversal protection

- Phase loss/open load protection

- Phase imbalance protection

- Shorted SCR protection

- Emergency stop functionality

- Automatic fault diagnostics

- Warning labels for safe operation

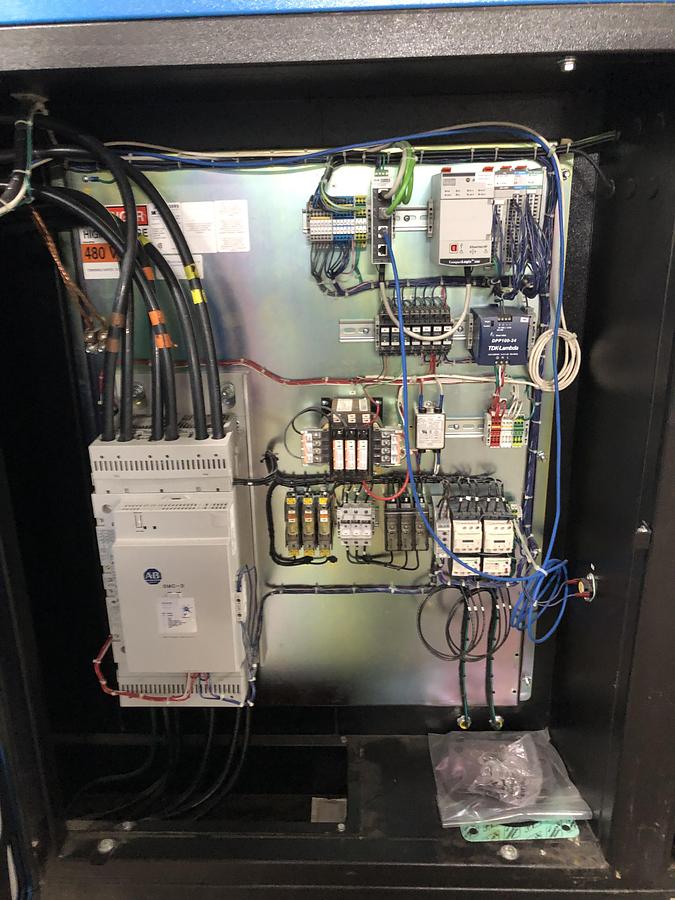

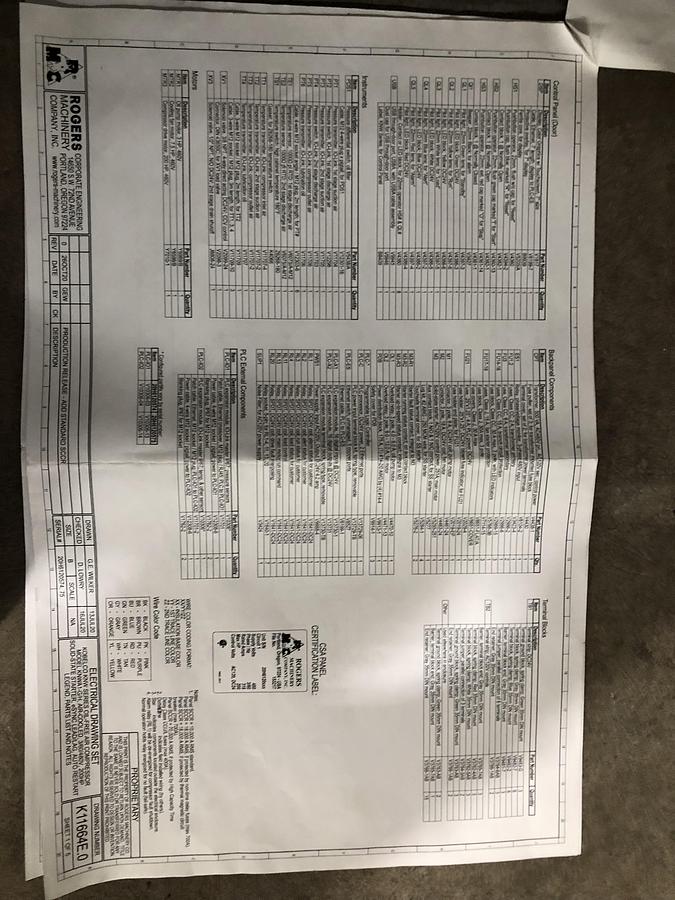

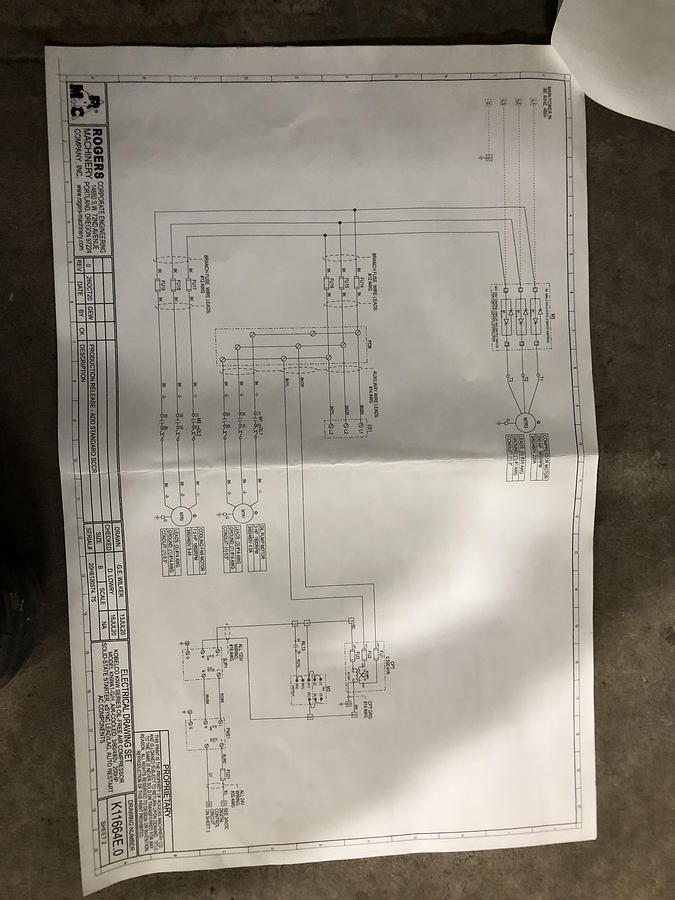

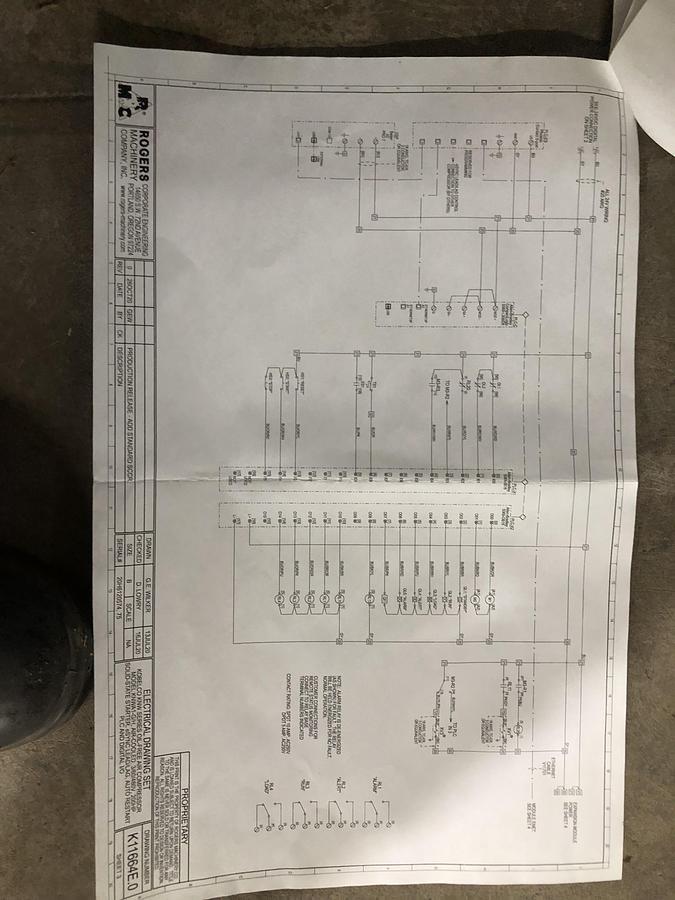

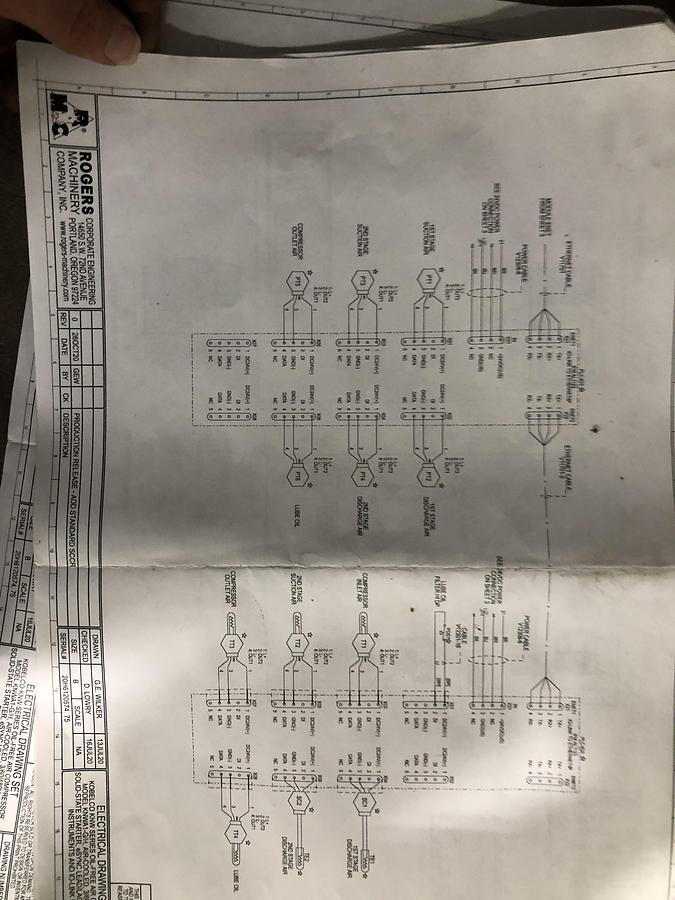

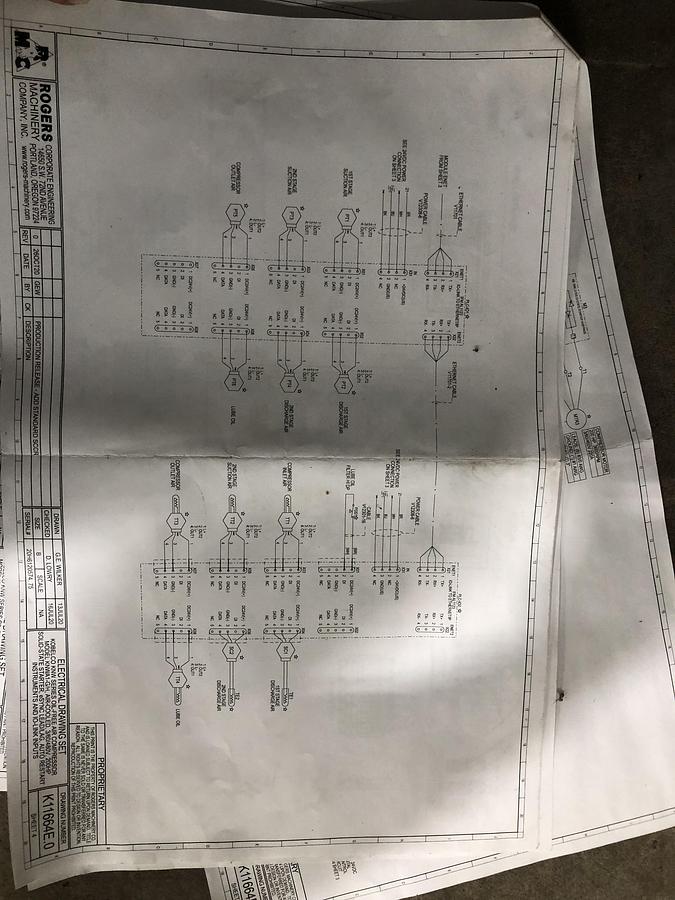

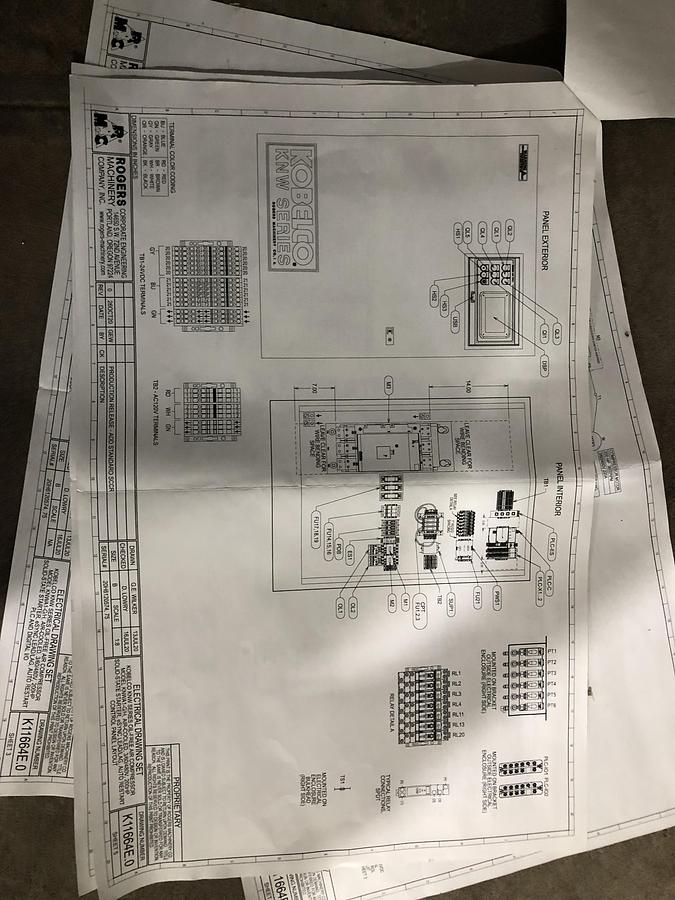

Electrical Schematics

Complete electrical schematics visible on control panel door including:

- Power distribution diagrams

- Control circuit layouts

- Motor connection diagrams

- Safety interlock circuits

- Component identification charts

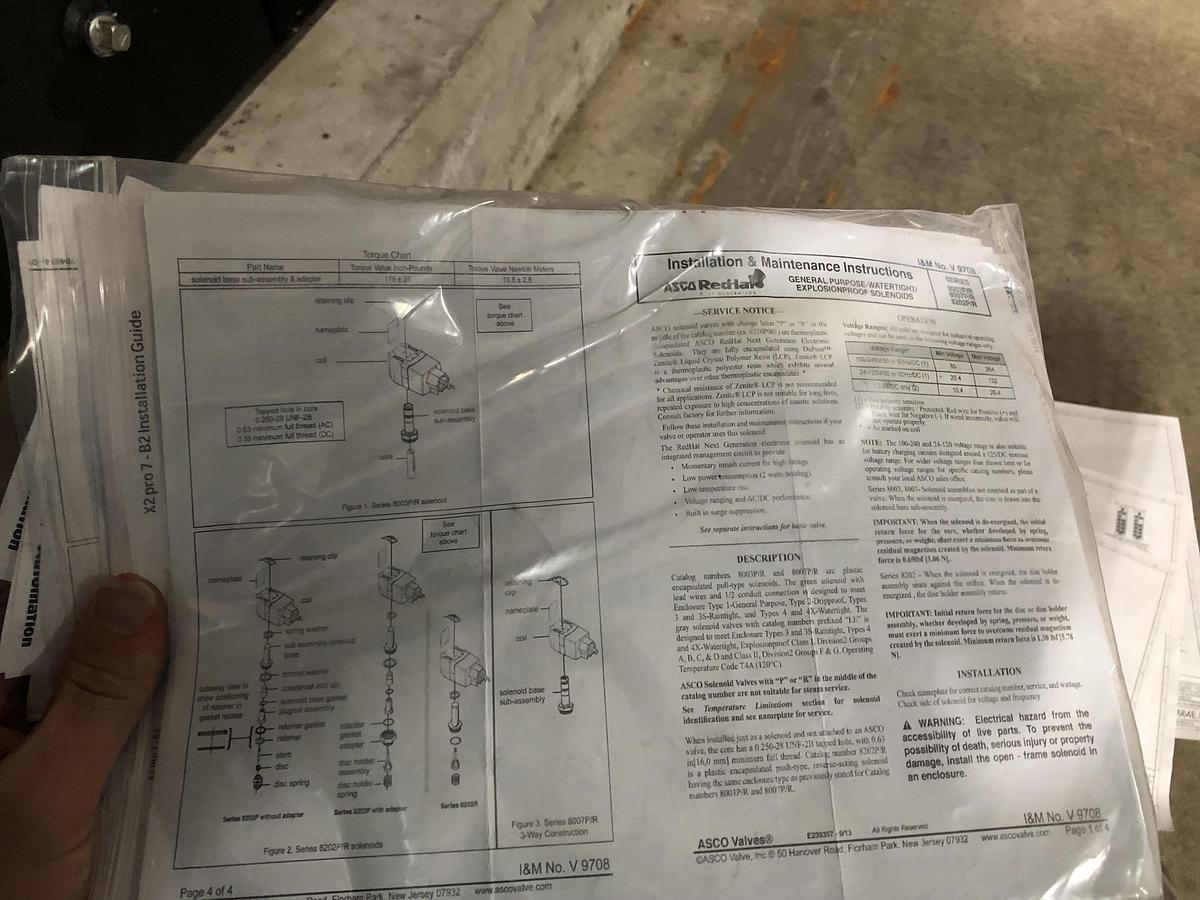

Documentation Included

- Electrical schematics (mounted on panel door)

- Safety warning labels

- Motor nameplate data

- Control system operation guides

- All technical specifications

Ideal Applications

- Food & Beverage Processing

- Pharmaceutical Manufacturing

- Electronics Manufacturing

- Medical Device Production

- Laboratory Air Supply

- Paint Spray Operations

- Chemical Processing

- Breathing Air Systems

- Any application requiring oil-free air

Benefits

- 100% oil-free compressed air

- No contamination risk

- Two-stage efficiency

- Advanced motor protection

- Comprehensive safety features

- User-friendly HMI interface

- Complete diagnostic capabilities

- Professional installation

Additional Information

Construction Features

- Heavy-duty steel enclosure in Quincy blue

- Integrated piping manifold

- Professional copper pipe installations

- Easy access control panel

- Robust industrial design

- Floor-mounted configuration

Maintenance Features

- Front access control panel

- Clear LED status indicators

- Diagnostic display on HMI

- Accessible electrical components

- Professional wiring installation

- Easy filter access

Location Details

- Facility: Room 1

- Unit Designation: Second Kobelco KNW unit

- Integration: Connected to facility compressed air system

Technical Details

- Model: AC-8202

- Motor: Baldor 36A00T552761

- Motor Protection: Allen-Bradley SMC-3

- Control Interface: KNW Series HMI

- Installation: Professional copper piping with isolation valves

Compliance & Standards

- NEMA Premium Efficiency Motor

- CSA Certified Components

- Energy Verified Motor

- Professional electrical installation

- Industrial safety standards compliance

- All safety labels and warnings in place

Specifications

| Manufacturer | Kobelco / Quincy (Rogers Machinery Co. Inc.) |

| Model | AC-8202 |

| Condition | Used |

| Stock Number | Site 1- Kobelco KNW Photos- #2 |