SPX FLOW Deltech Compressed Air Dryer System HCS-930

SPX FLOW Deltech Compressed Air Dryer System HCS-930

Contact us for price

Location:Ohio

or

Call 305-428-2777

Description

Overview

This SPX FLOW Deltech HCS-930 is a commercial-grade pressure-swing regenerative desiccant compressed air dryer system designed for efficient moisture removal in industrial compressed air applications. The system features dual desiccant towers with activated alumina media for continuous operation and reliable dew point control. This is a complete compressed air treatment system ready for installation.

Design and Performance

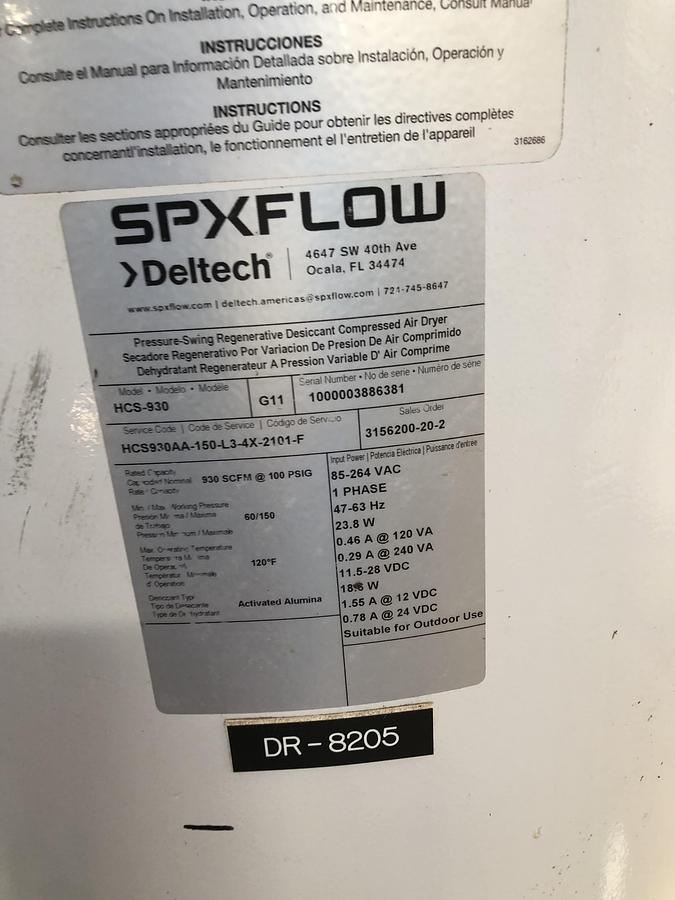

- Manufacturer: SPX FLOW / Deltech

- Location: Ocala, FL 34474

- Model: HCS-930

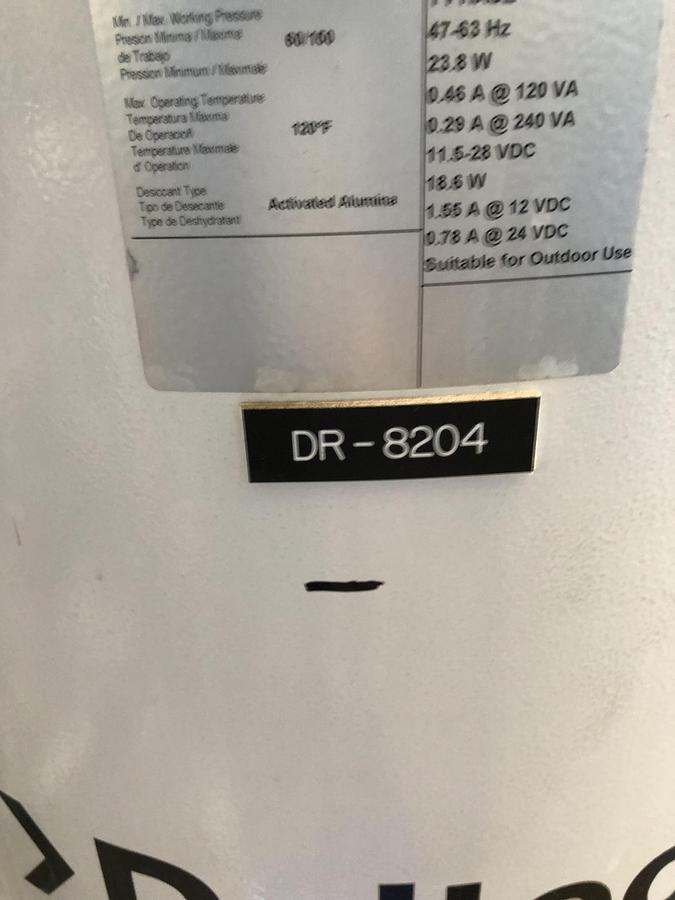

- Serial Numbers:Unit 1 (DR-8204): 1000003886380

- Unit 2 (DR-8205): 1000003886381

- Type: Pressure-Swing Regenerative Desiccant Air Dryer

- Construction: Heavy-duty steel vessels with powder-coated finish

- Desiccant Type: Activated Alumina

Key Specifications

- Condition: Used - Commercial Grade

- Performance Specifications:Rated Capacity: 930 SCFM @ 100 PSIG

- Operating Pressure: 60-150 PSIG

- Maximum Operating Temperature: 120°F

- Electrical: 85-264 VAC, 1 Phase, 47-63 Hz

- Power Consumption: 23.8W @ 120VA, 0.46A @ 120V

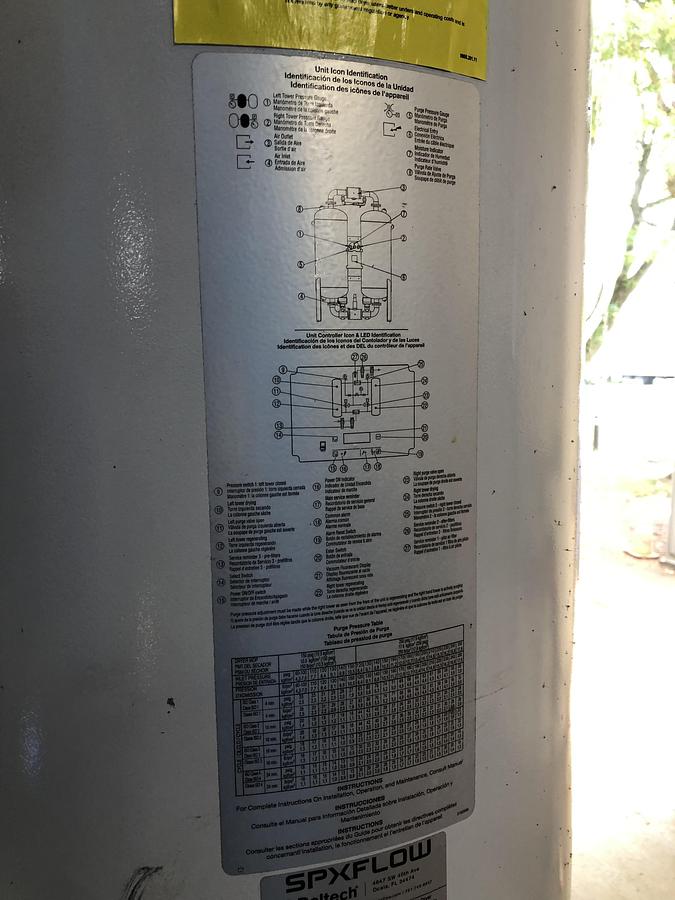

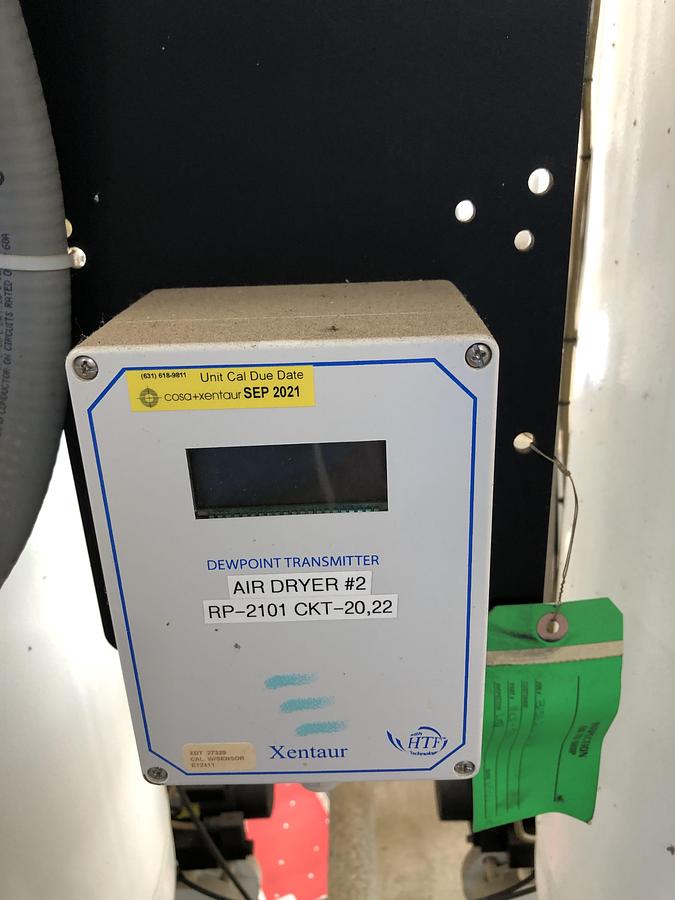

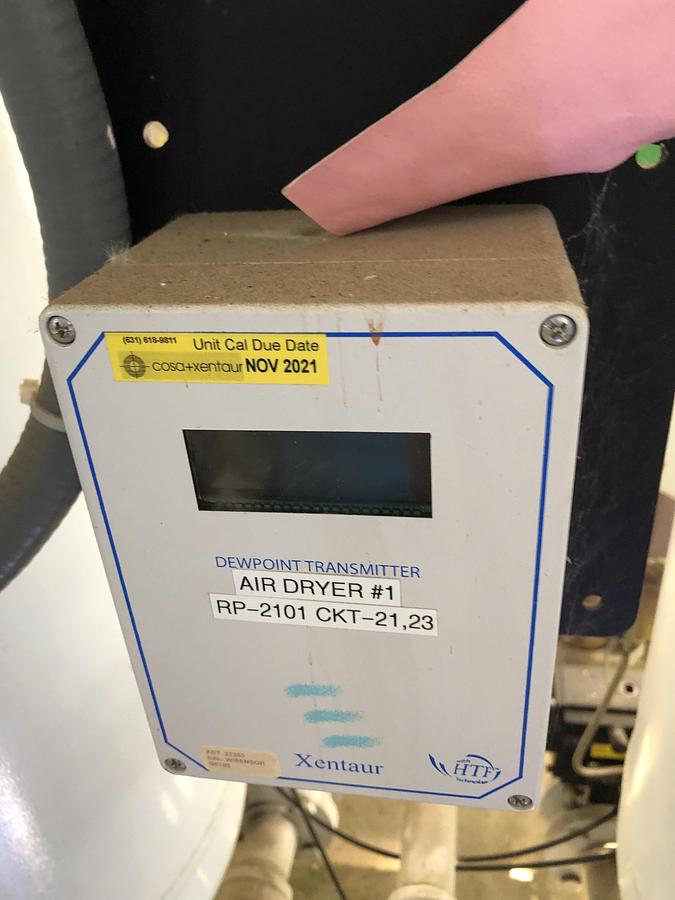

- Control System:Digital control panel (Model RP-2101)

- Dewpoint transmitter monitoring

- Automatic regeneration cycles

- LED status indicators

System Components

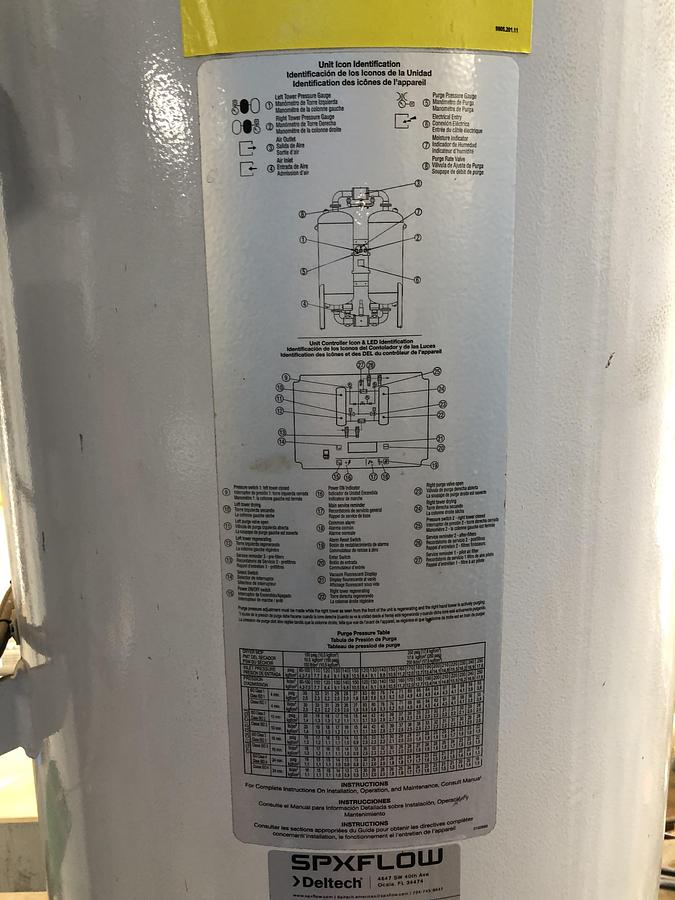

- Dual Tower Configuration:Two desiccant vessels for continuous operation

- Automatic tower switching

- Pressure swing regeneration

- Filtration System:Pre-filters and after-filters

- Coalescing elements

- Particulate removal stages

- Control Features:Microprocessor-based controller

- Digital display interface

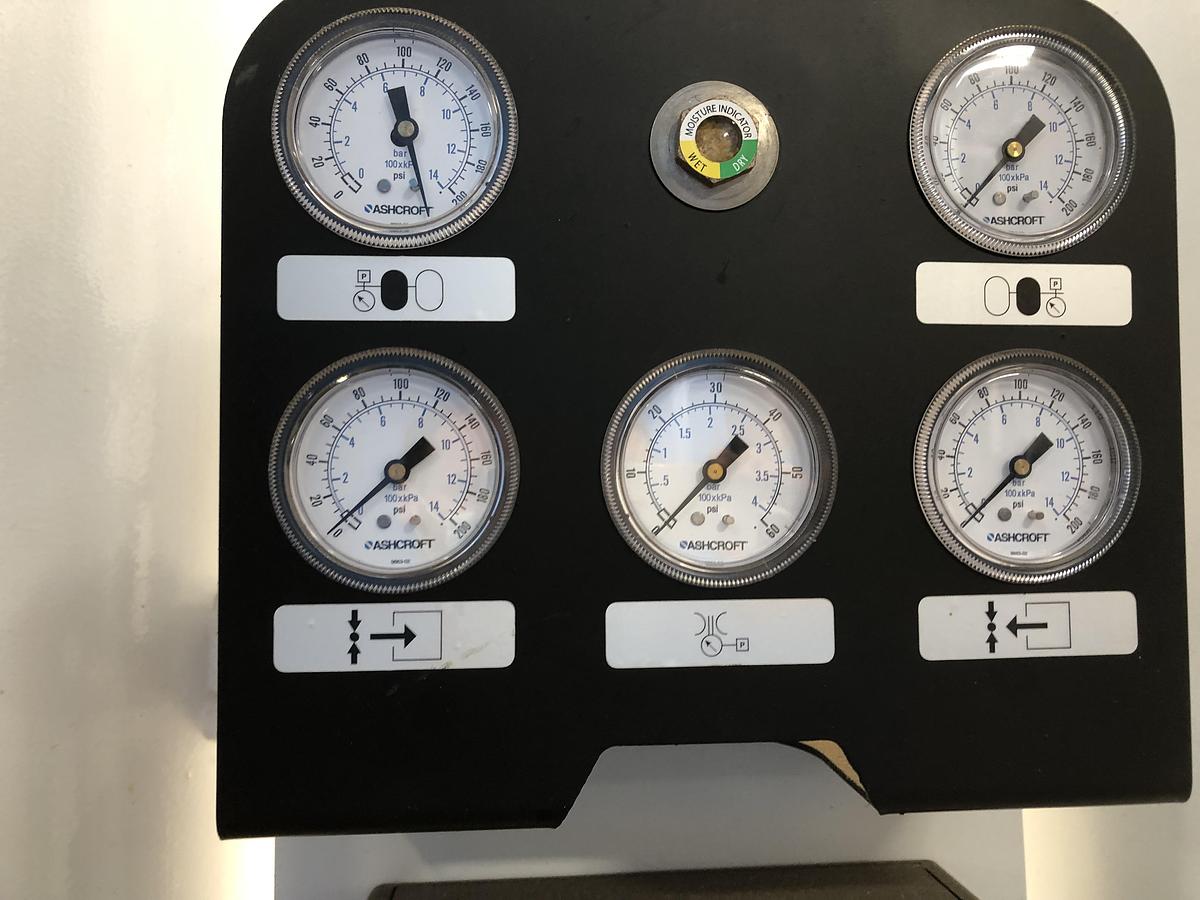

- Ashcroft pressure gauges (0-14 PSI range)

- Moisture indicator

- Automatic purge controls

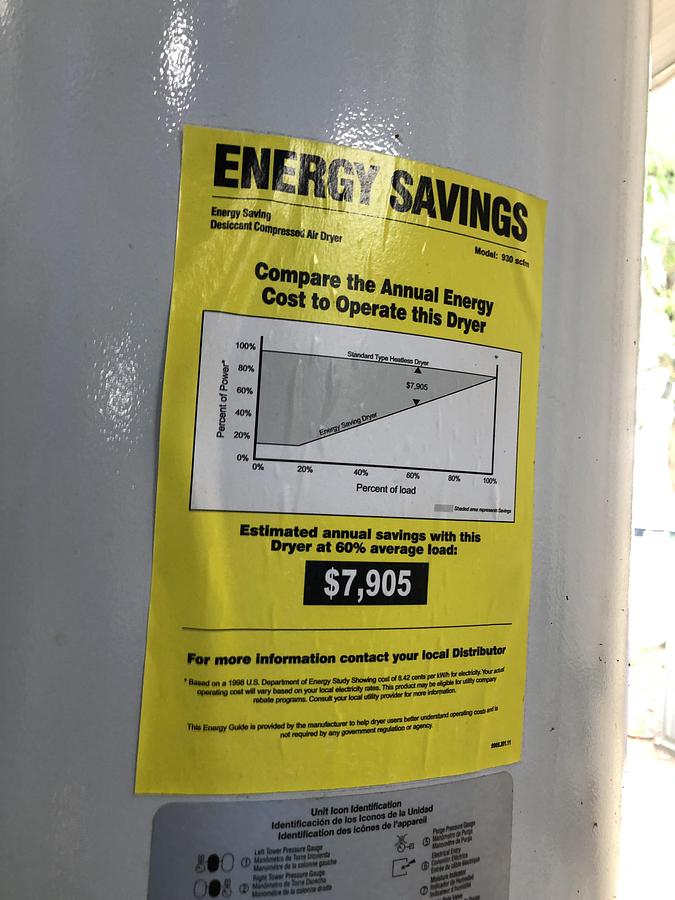

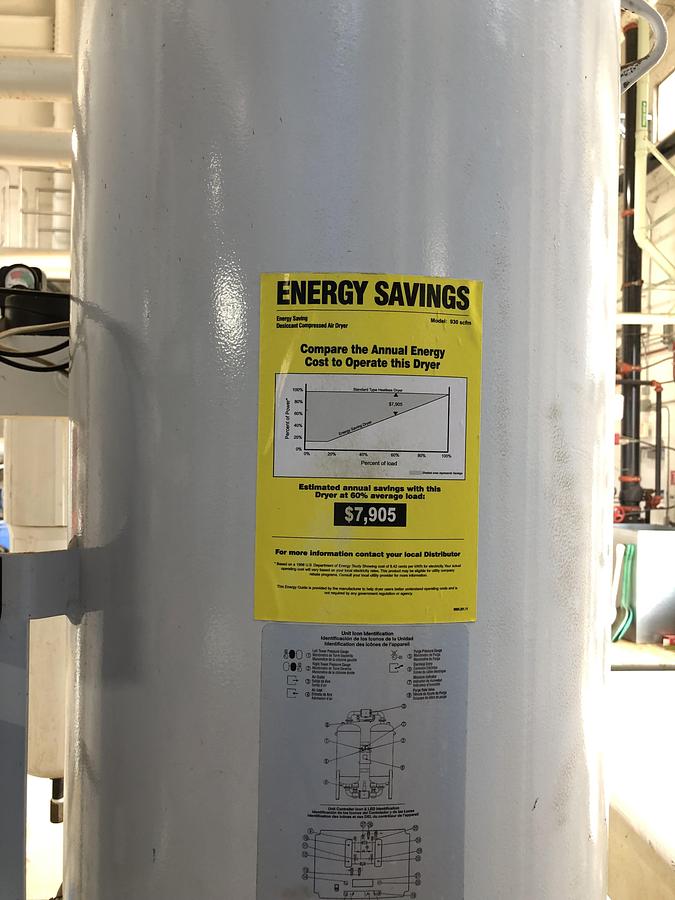

Energy Efficiency

- Energy Savings Technology: Pressure-swing design minimizes compressed air loss

- Annual Energy Savings: $7,905 estimated at 60% average load

- Suitable for Outdoor Use: Yes

- Low Power Consumption: Only 23.8W operating power

Safety Features

- Multiple pressure gauges for system monitoring

- Over-pressure protection

- Automatic shut-off valves

- Safety relief valves

- Comprehensive warning labels

- Unit calibration tracking (November 2021)

Ideal Applications

- Manufacturing Facilities

- Automotive Plants

- Food & Beverage Processing

- Pharmaceutical Production

- Electronics Manufacturing

- Painting & Coating Operations

- Pneumatic Tool Operation

- Instrument Air Systems

- Process Air Applications

Benefits

- Continuous operation with dual towers

- Energy-efficient regeneration

- Low pressure drop design

- Minimal compressed air loss

- Digital monitoring and control

- Reliable dew point performance

- Long desiccant life

- Easy maintenance access

- Complete filtration package

Additional Information

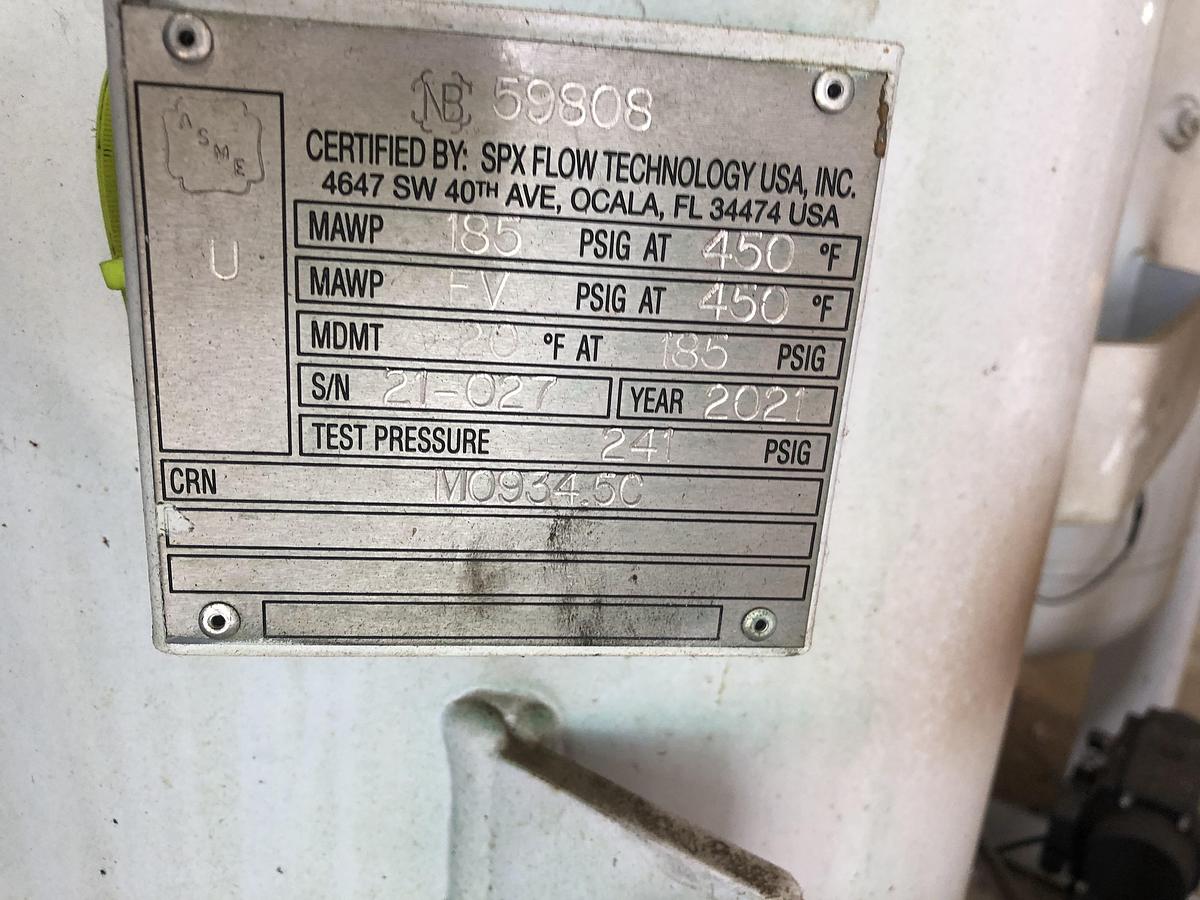

- Construction Features:ASME coded pressure vessels

- Powder-coated steel construction

- Stainless steel valves

- High-efficiency desiccant media

- Heavy-duty solenoid valves

- Integrated pre and after filters

- Included Components:Two complete desiccant towers

- Digital control system

- Dewpoint monitoring system

- Complete valve assembly

- Inlet/outlet connections

- Pressure gauges

- Filtration elements

- Service manual

- Control System Features:Xentaur dewpoint transmitters

- Circuit identification (CKT-20.22, CKT-21.23)

- LED status display

- Programmable regeneration cycles

- Service interval tracking

- Fault diagnostics

- Service Features:Quincy Scales Industrial service support

- 24-hour service available (866-890-1010)

- Clear component identification

- Easy filter access

- Standard connections

Maintenance Requirements

- Desiccant: Replace activated alumina as needed

- Filters: Change pre/after filters per differential pressure

- Valves: Annual inspection and testing

- Controller: Calibration verification annually

- Dewpoint Monitor: Calibration due November 2021

Technical Details from Images

- Model: HCS-930

- Service Code: HCS930AA-150-L3-4X-2101-F

- Electrical: 85-264 VAC, 1 Phase

- Flow Capacity: 930 SCFM @ 100 PSIG

- Installation: Indoor/Outdoor suitable

- Controls: Digital with dewpoint monitoring

- Pressure Range: 60-150 PSIG operating

Energy Savings Data

- 60% Load Operation: $7,905 annual savings

- Standard Heatless Dryer Comparison: Significant energy reduction

- Based on: DOE energy study data

- Operating Cost: Substantially lower than standard designs

Specifications

| Manufacturer | SPX FLOW / Deltech |

| Model | HCS-930 |

| Condition | Used |

| Stock Number | Site 1- #13 |