PROASYS Industrial Water Treatment System with Chemical Feed Equipment

PROASYS Industrial Water Treatment System with Chemical Feed Equipment

Contact us for price

Location:Ohio

Description

Overview

This complete PROASYS water treatment system is a professional-grade industrial water treatment solution designed for commercial and industrial applications. The system includes automated chemical feed equipment with dual chemical storage tanks, digital monitoring capabilities, and a complete control system. With real-time flow monitoring showing over 6 million gallons processed, this system provides reliable water treatment for facilities requiring precise pH control and water conditioning.

System Components

Main Treatment Vessels

- Multiple stacked treatment vessels with resin/media beds

- Industrial-grade construction with protective coating

- Staged treatment configuration for optimal efficiency

- Service platforms and access ladders included

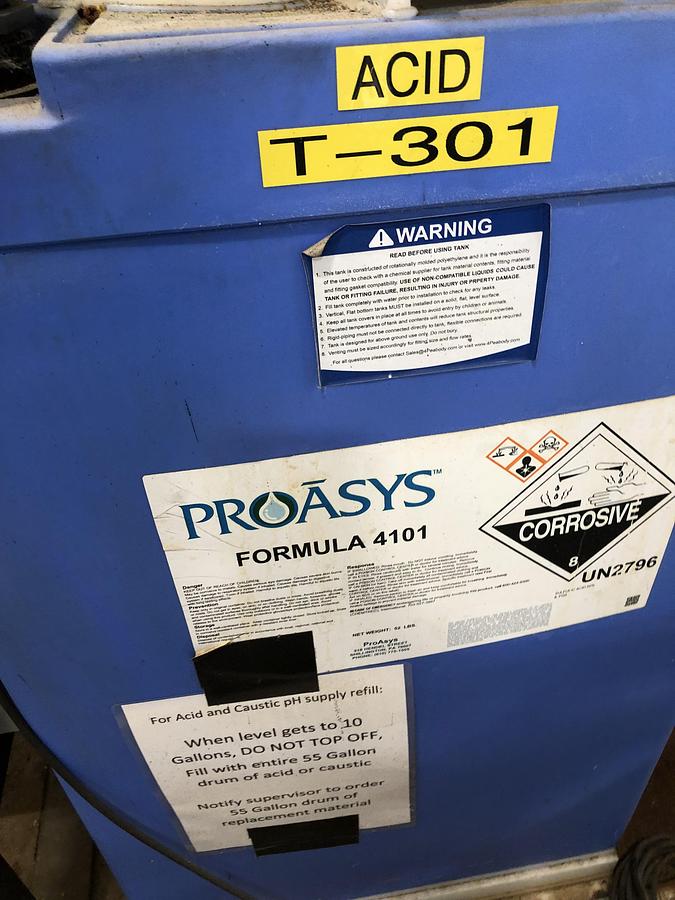

Chemical Feed System

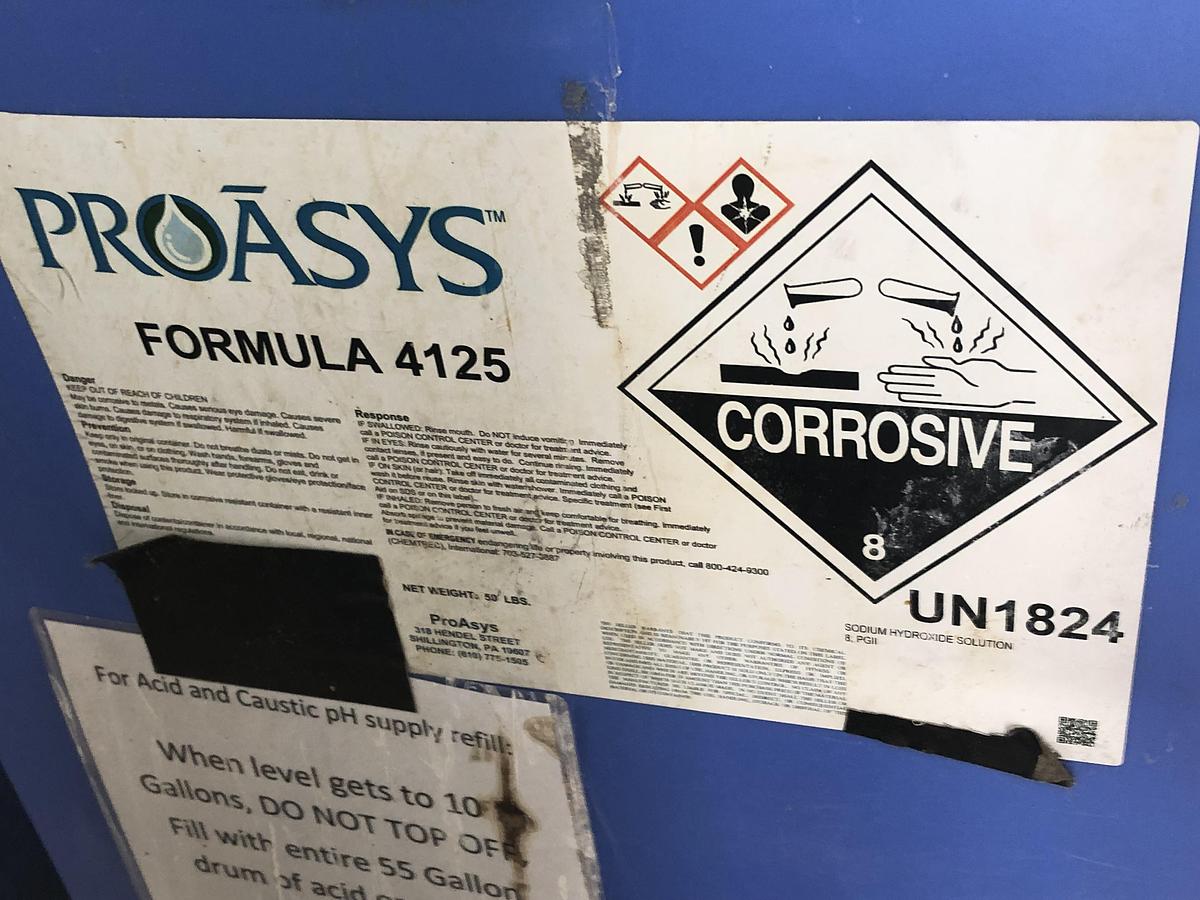

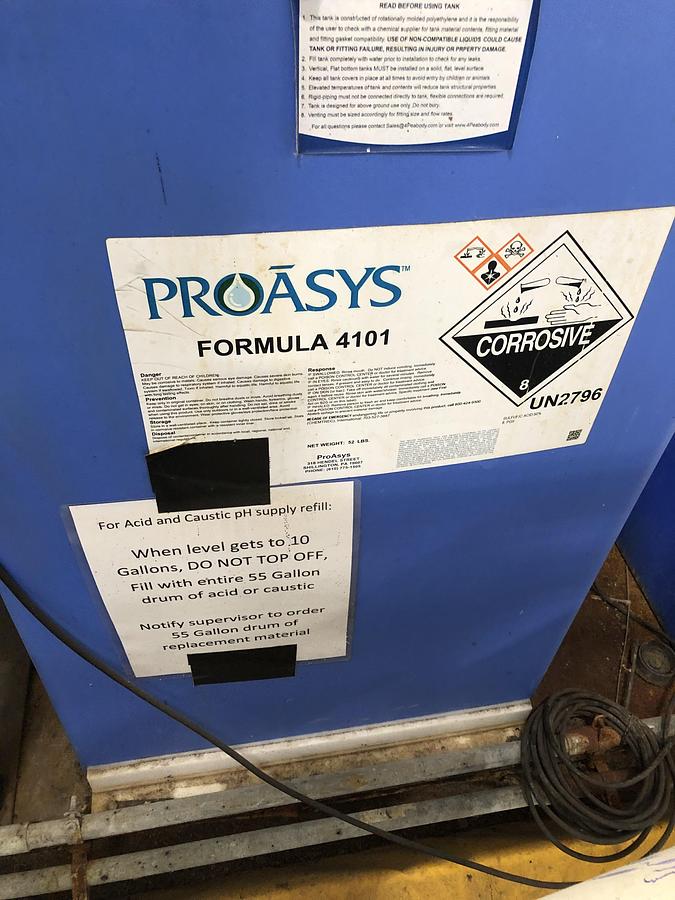

- Dual Chemical Storage TanksTank 1 (T-301): Acid storage with ProAsys Formula 4101 (UN2796 Corrosive)

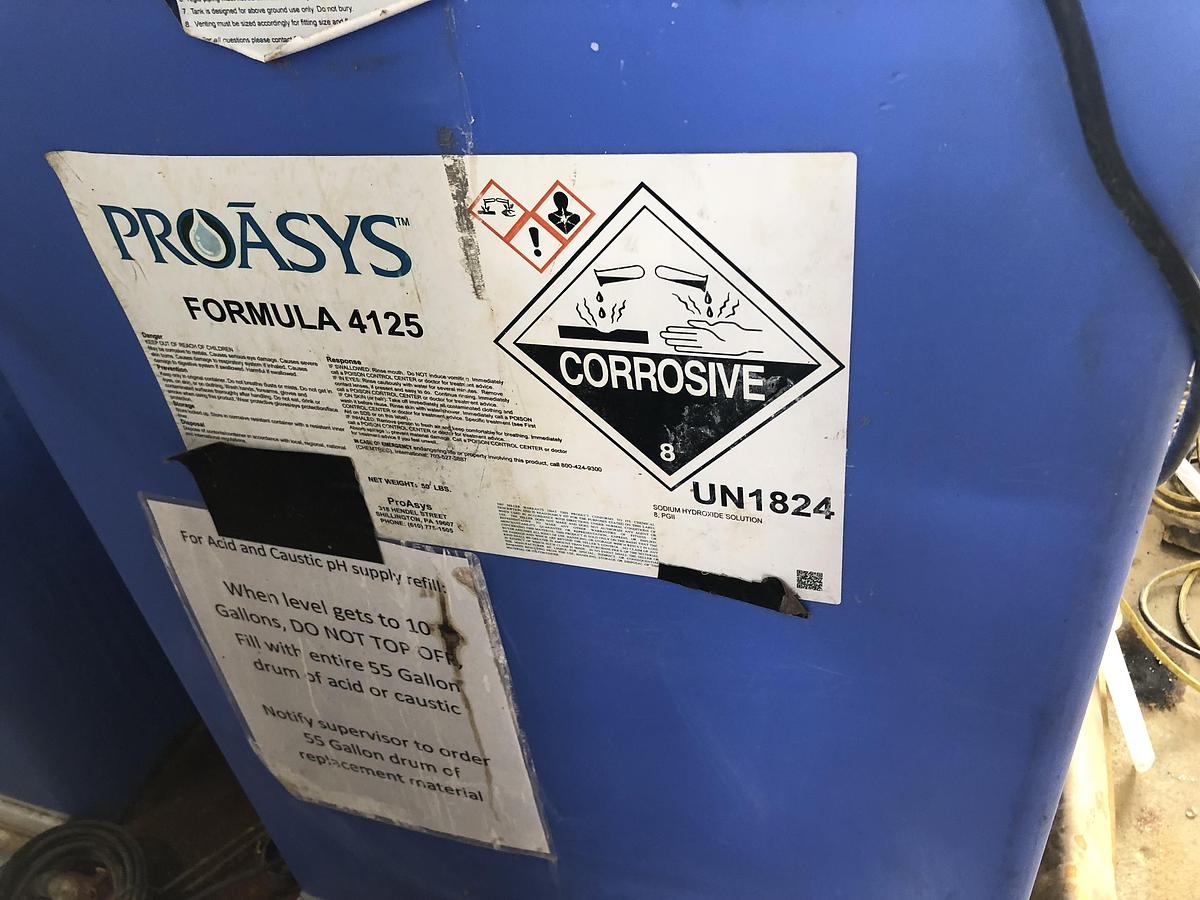

- Tank 2: ProAsys Formula 4125 (UN1824 Sodium Hydroxide Solution)

- Capacity: 55-gallon drums for each chemical

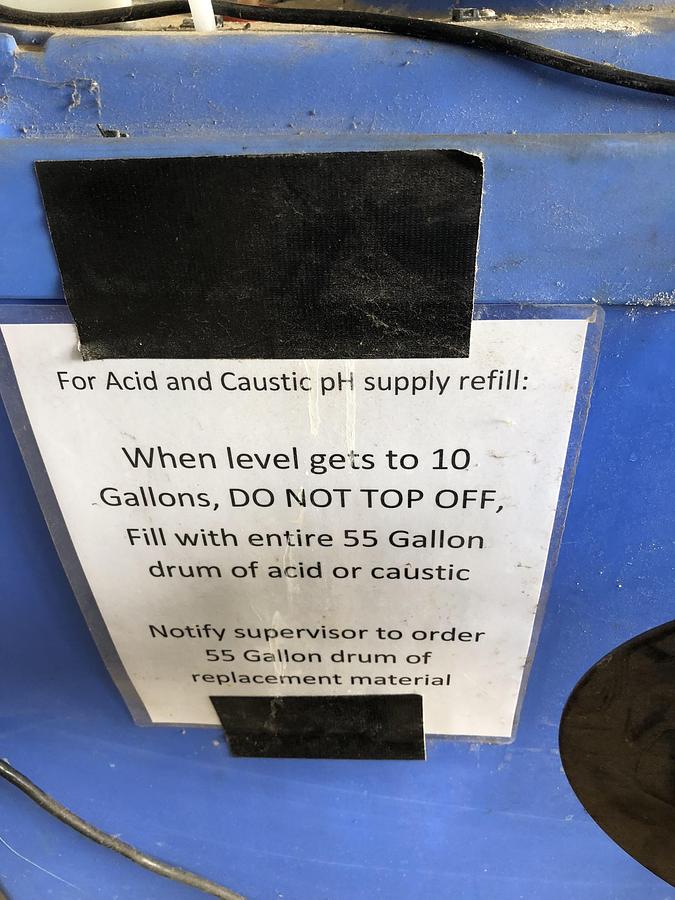

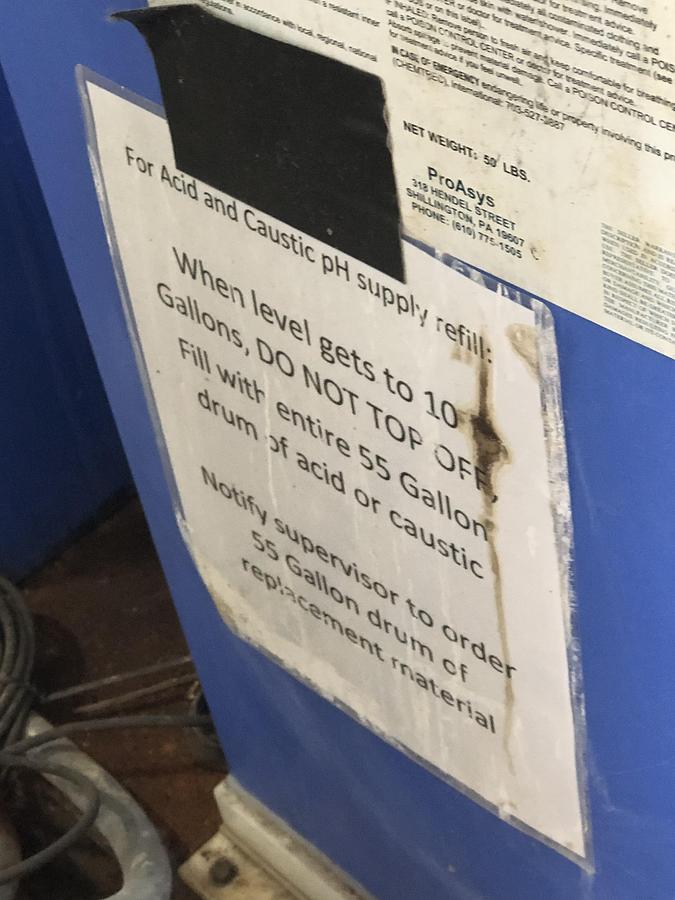

- Automated refill alerts at 10-gallon level

- Safety features: Corrosive material warnings and spill containment

Control System

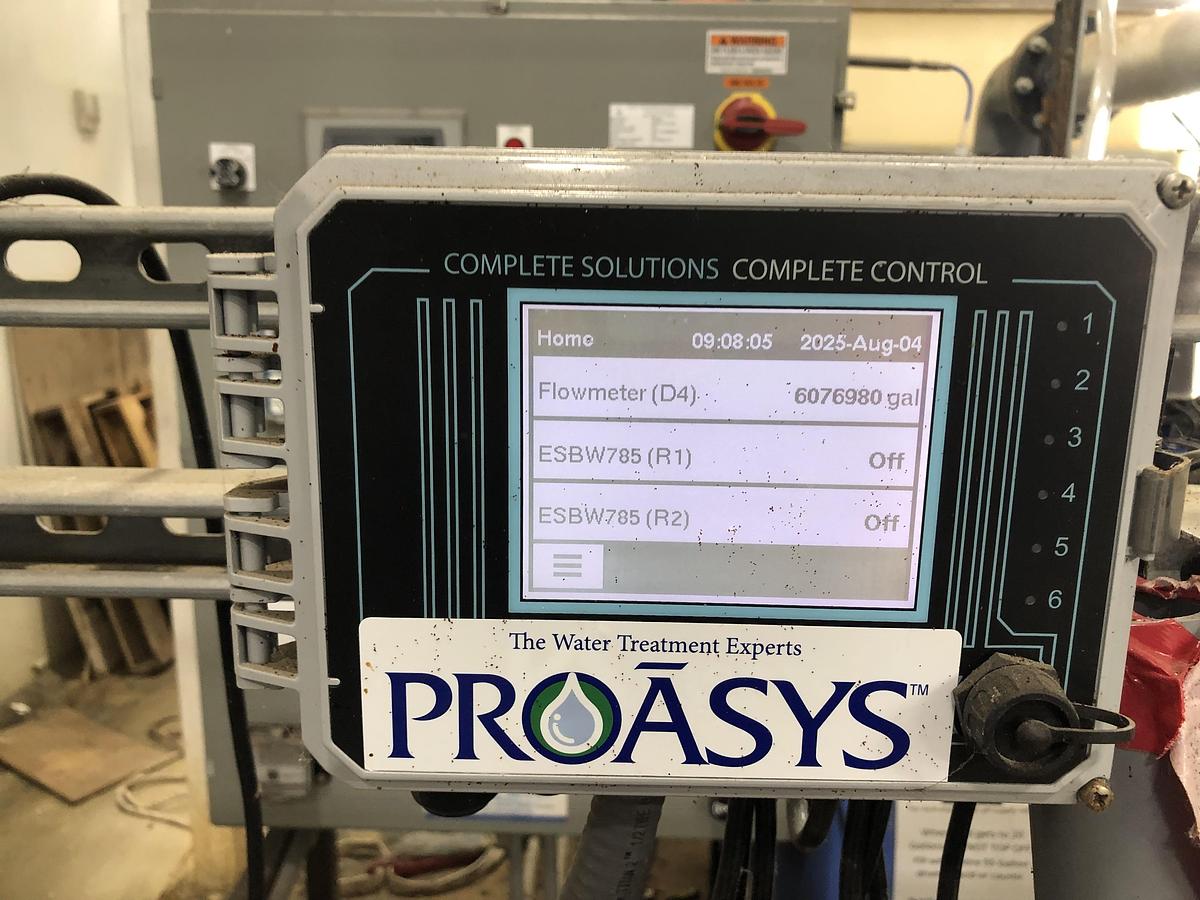

- Brand: ProAsys - The Water Treatment Experts

- Display: Digital touchscreen control panel

- Monitoring: Real-time flow meter showing 6,076,980 gallons processed

- Date: System showing operation as of August 4, 2025

- Features: "Complete Solutions Complete Control" interface

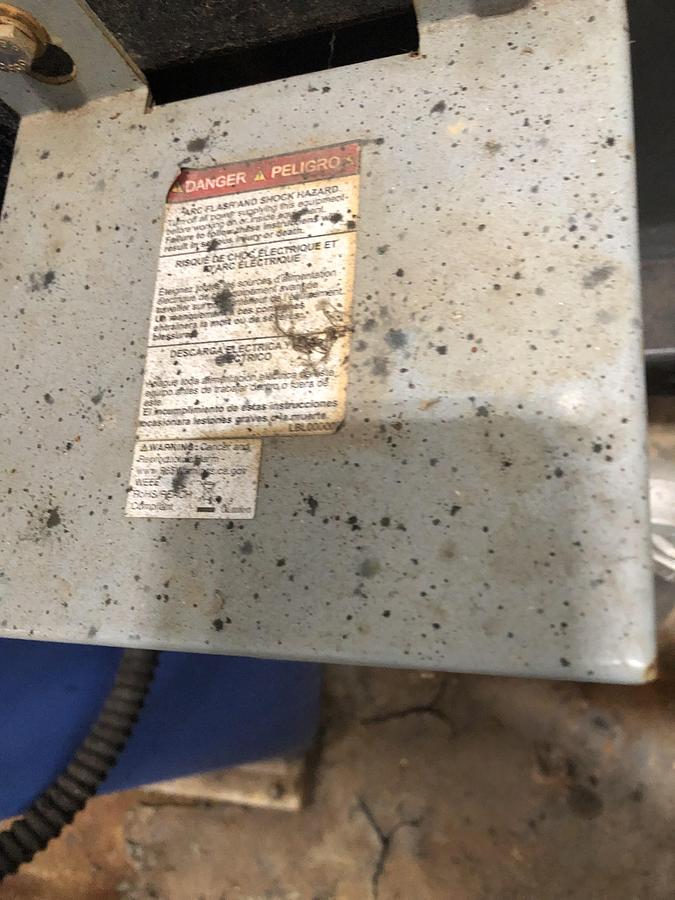

Electrical Components

- Hammond Power Solutions HPS Fortress TransformerModel: Commercial Potted Distribution Transformer

- Primary: 240V x 480V

- Secondary: 120V/240V

- Rating: 1.5 kVA

- Type: Q (Quiet operation)

- Temperature Rise: 180°C

- Frequency: 60 Hz

- Impedance: 4.1%

- CSA and UL Listed

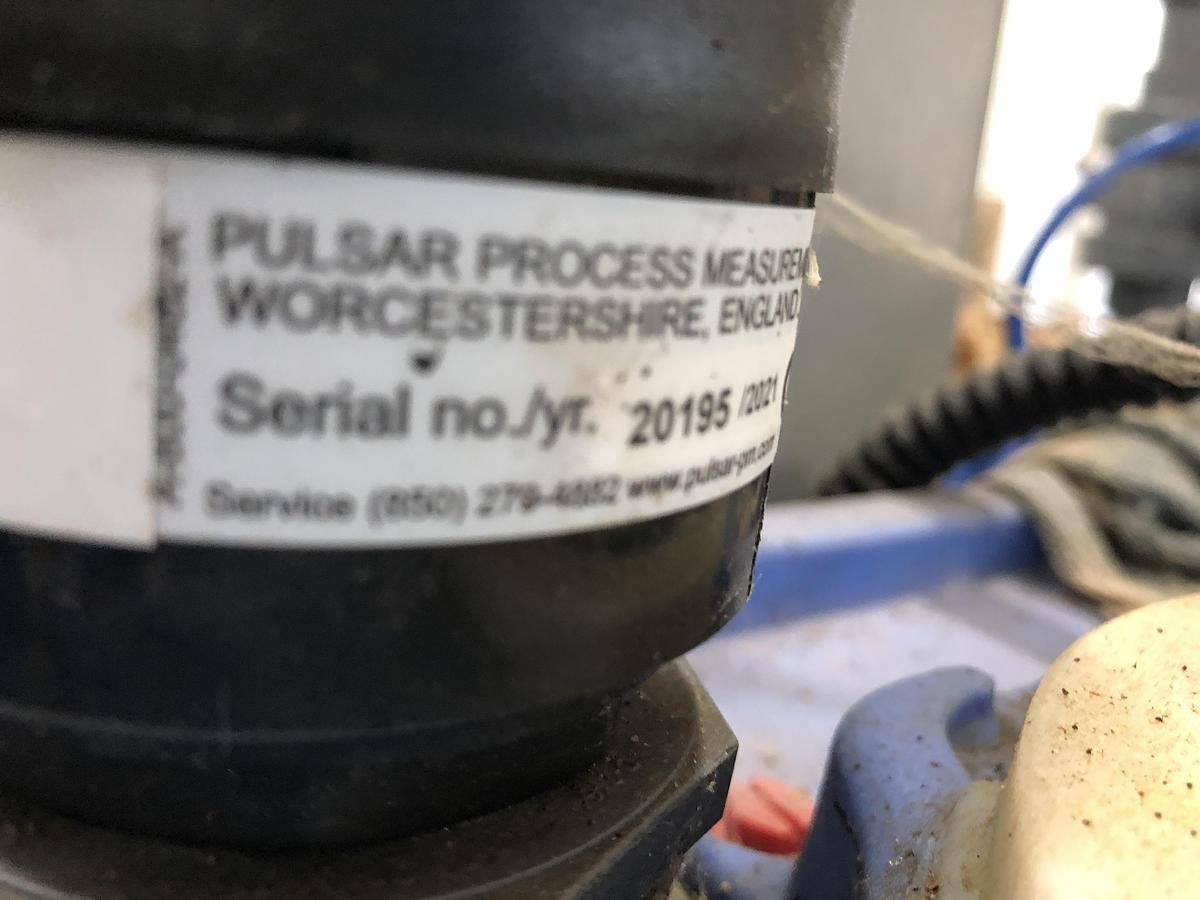

Monitoring Equipment

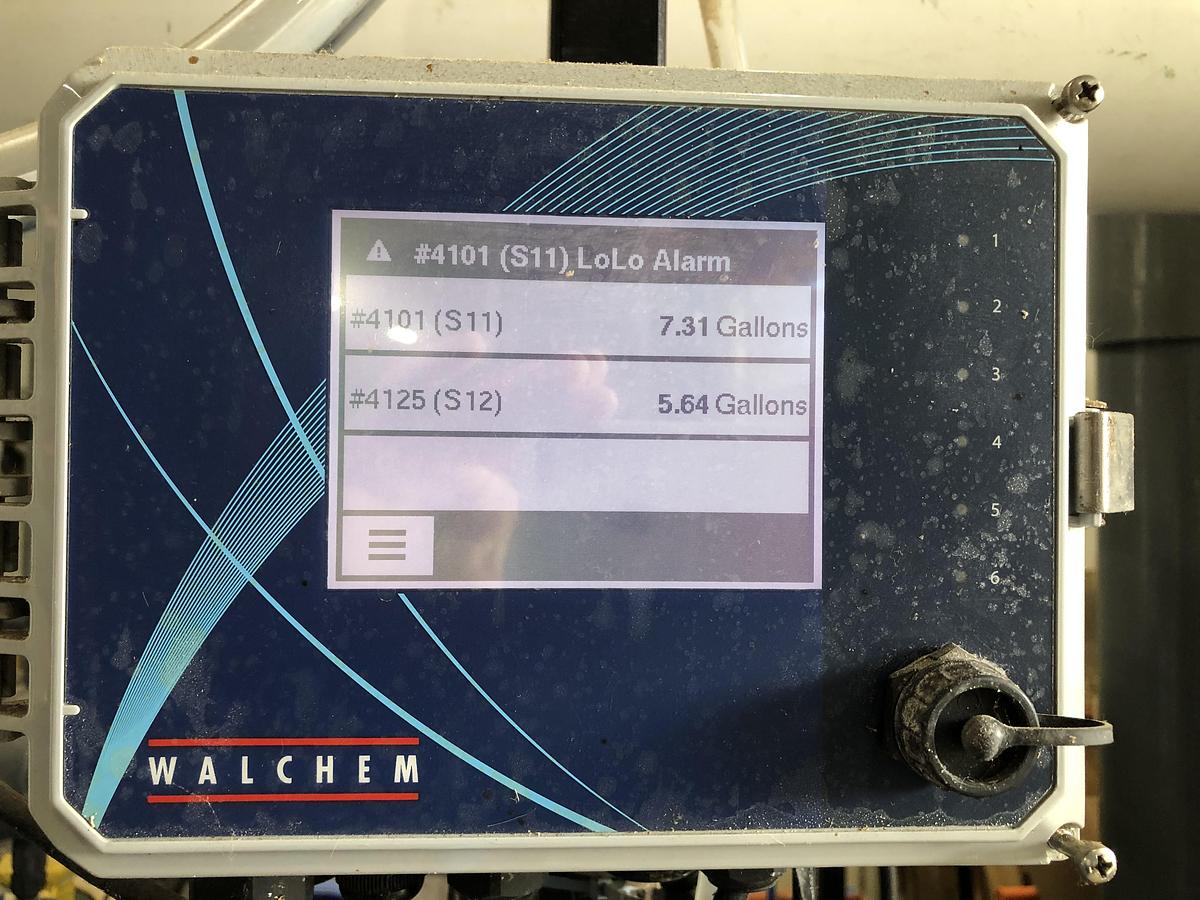

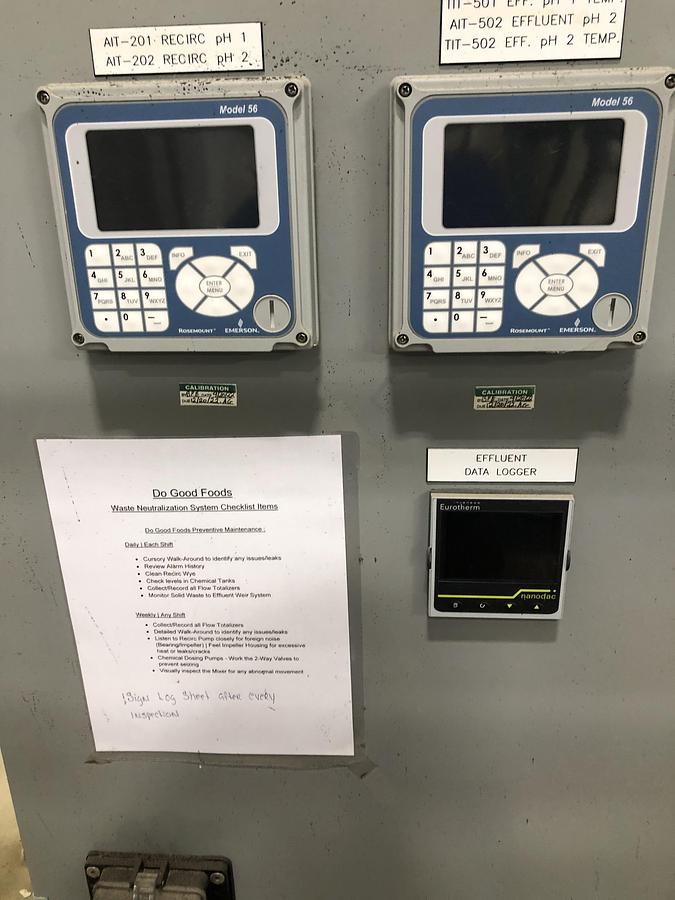

- Walchem ControllerDigital display with alarm capabilities

- Tank level monitoring (#4101 S11 and #4125 S12)

- Low-level alarm system (LoLo Alarm)

- Real-time gallon tracking

Technical Specifications

Process Conditions

- Power Rating: 24 VDC

- Output: 4-20mA 4 SPST Relay

- Process Temperature: -40 to 176°F

- Process Pressure: 30 PSI

- Enclosure Rating: IP68

- Wetted Materials: PVDF, Viton GLT

Chemical Specifications

- Acid Tank: ProAsys Formula 4101 (Corrosive Class 8)

- Caustic Tank: ProAsys Formula 4125 (Sodium Hydroxide)

- Refill Protocol: Complete 55-gallon drum replacement when level reaches 10 gallons

Key Features

- Professional ProAsys water treatment technology

- Automated pH control with acid/caustic feed

- Digital monitoring and control system

- Over 6 million gallons of proven operation

- Dual chemical storage with automatic low-level alerts

- Industrial-grade construction

- Complete electrical and control package

- Real-time flow monitoring

- Safety features including warning labels and containment

System Benefits

- Precise pH control for industrial processes

- Automated operation reduces labor costs

- Proven reliability with millions of gallons treated

- Complete turnkey solution

- Professional-grade components throughout

- Digital monitoring for easy operation

- Safety-focused design with proper labeling

- Expandable and serviceable design

Ideal Applications

- Industrial Manufacturing Facilities

- Food and Beverage Processing

- Chemical Processing Plants

- Power Generation Facilities

- Pharmaceutical Manufacturing

- Commercial Laundries

- Cooling Tower Treatment

- Boiler Feed Water Treatment

- Process Water Treatment

- Any facility requiring precise water chemistry control

Safety Features

- Corrosive material warnings (UN2796 and UN1824)

- Proper chemical labeling and hazard communication

- Low-level alarms to prevent pump damage

- Spill containment considerations

- IP68 rated components for wet environments

- Professional electrical installation with transformer

Included Equipment

✓ Multiple treatment vessels with media

✓ ProAsys digital control system

✓ Dual 55-gallon chemical storage tanks

✓ Chemical feed pumps and equipment

✓ Walchem monitoring controller

✓ Hammond 1.5 kVA transformer

✓ Complete piping and valve assemblies

✓ Flow meter with totalization

✓ Safety signage and warnings

✓ Access platforms and supports

Operating History

- Current total flow: 6,076,980 gallons

- System date showing: August 4, 2025

- Active monitoring of chemical levels

- Proven operational reliability

Condition Notes

- Industrial facility installation

- Blue protective coating on tanks

- Complete with all safety labeling

- Professional installation with proper supports

- Operational control system

- Some weathering visible but fully functional

Safety Notice

This system handles corrosive chemicals. Operation requires trained personnel familiar with chemical handling procedures. Follow all posted warnings and use appropriate PPE. Maintain proper chemical inventory and follow refill procedures as posted.

Specifications

| Manufacturer | PROASYS |

| Condition | Used |

| Stock Number | Site 1- #1 |