Altair Industrial Boiler System with Integrated Water Treatment

Altair Industrial Boiler System with Integrated Water Treatment

Contact us for price

Location:Ohio

Description

Overview

This Altair Industrial Boiler System features a dual boiler configuration with integrated water treatment controls, designed for commercial and industrial facilities requiring reliable steam or hot water generation. The system includes two heavy-duty Altair boilers with AECO water treatment technology, Allen-Bradley PanelView Plus control interfaces, and CentriPro Aquavar variable frequency drives. Complete with hazardous energy control procedures, professional installation, and comprehensive safety systems, this package is suitable for hospitals, manufacturing facilities, universities, and other critical infrastructure applications.

Design and Performance

Boiler Specifications (Per Unit)

- Manufacturer: Altair Equipment Co., Inc.

- Type: Industrial Water Tube Boiler

- Configuration: Dual boiler setup

- Mounting: Chain-suspended with seismic restraints

- Insulation: Full thermal jacket with metal cladding

- Controls: Integrated safety and operational controls

- Service: Continuous duty rated

- Installation: Professional grade with full documentation

Water Treatment System

- Manufacturer: AECO Altair Equipment Co., Inc.

- Location: Warminster, PA 18974

- Phone: (800) 673-7879

- Interface: PanelView Plus 600 touchscreen

- Pumps: Dual feedwater and transfer pumps

- Control: Automated chemical feed system

- Bypass: Solenoid valve (Open 65°/Close 75°)

Complete System Package

Main Components

- Two (2) Altair industrial boilers

- AECO water treatment control system

- Four (4) pump assemblies (2 feedwater, 2 transfer)

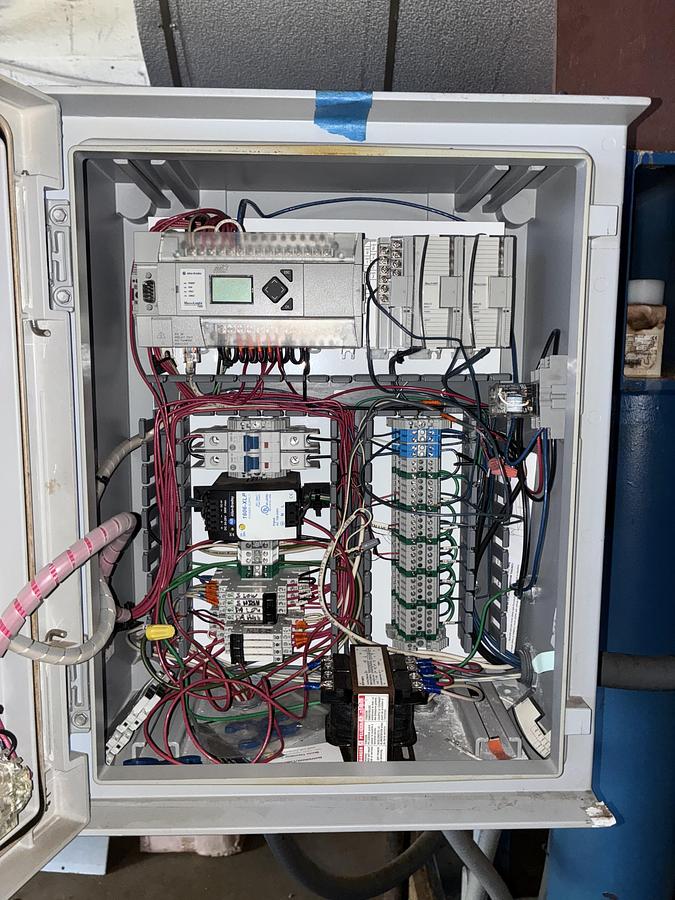

- Allen-Bradley control panels

- CentriPro Aquavar VFD units

- Complete piping assemblies

- Isolation and control valves

- Pressure and temperature monitoring

- Professional installation framework

Control System

- HMI: Allen-Bradley PanelView Plus Compact 600

- Model: 2711PC-T6C20D8

- Configuration: Multiple control stations

- Operation: Automated with manual override

- Protection: Explosion-proof enclosures where required

- Monitoring: Real-time system parameters

Key Features

System Configuration

- Type: Dual boiler lead/lag operation

- Redundancy: 100% backup capability

- Control: Fully automated sequencing

- Efficiency: Optimized firing control

- Safety: Multiple interlock systems

- Monitoring: Comprehensive instrumentation

System Benefits

- Continuous steam/hot water availability

- Automatic backup operation

- Energy-efficient VFD control

- Reduced chemical usage

- Extended equipment life

- Professional grade components

- Minimal operator intervention

System Specifications

Operating Parameters

- Service: Steam or hot water

- Pressure: Per system design

- Temperature: Industrial rated

- Efficiency: High efficiency design

- Turndown: Excellent modulation

- Response: Fast load following

Control Features

- VFDs: CentriPro Aquavar units

- Interface: Touchscreen HMI

- Communication: Industrial protocols

- Safety: SIL-rated interlocks

- Monitoring: Trend logging capability

- Alarms: Comprehensive fault detection

Ideal Applications

- Healthcare Facilities

- Manufacturing Plants

- Universities & Schools

- Office Complexes

- Industrial Processes

- District Heating

- Food Processing

- Pharmaceutical Production

- Any facility requiring reliable steam/hot water

Installation Features

Mechanical Installation

- Professional suspended mounting

- Seismic restraint systems

- Industrial grade piping

- Full insulation systems

- Proper drainage provisions

- Service access platforms

Electrical Integration

- VFD motor control

- Safety interlock wiring

- Control panel mounting

- Proper grounding systems

- NEC compliant installation

- Emergency shutdown circuits

Operational Advantages

Automation Benefits

- Reduced operator requirements

- Optimized efficiency

- Predictive maintenance alerts

- Remote monitoring capable

- Automatic lead/lag rotation

- Load-based sequencing

Safety Features

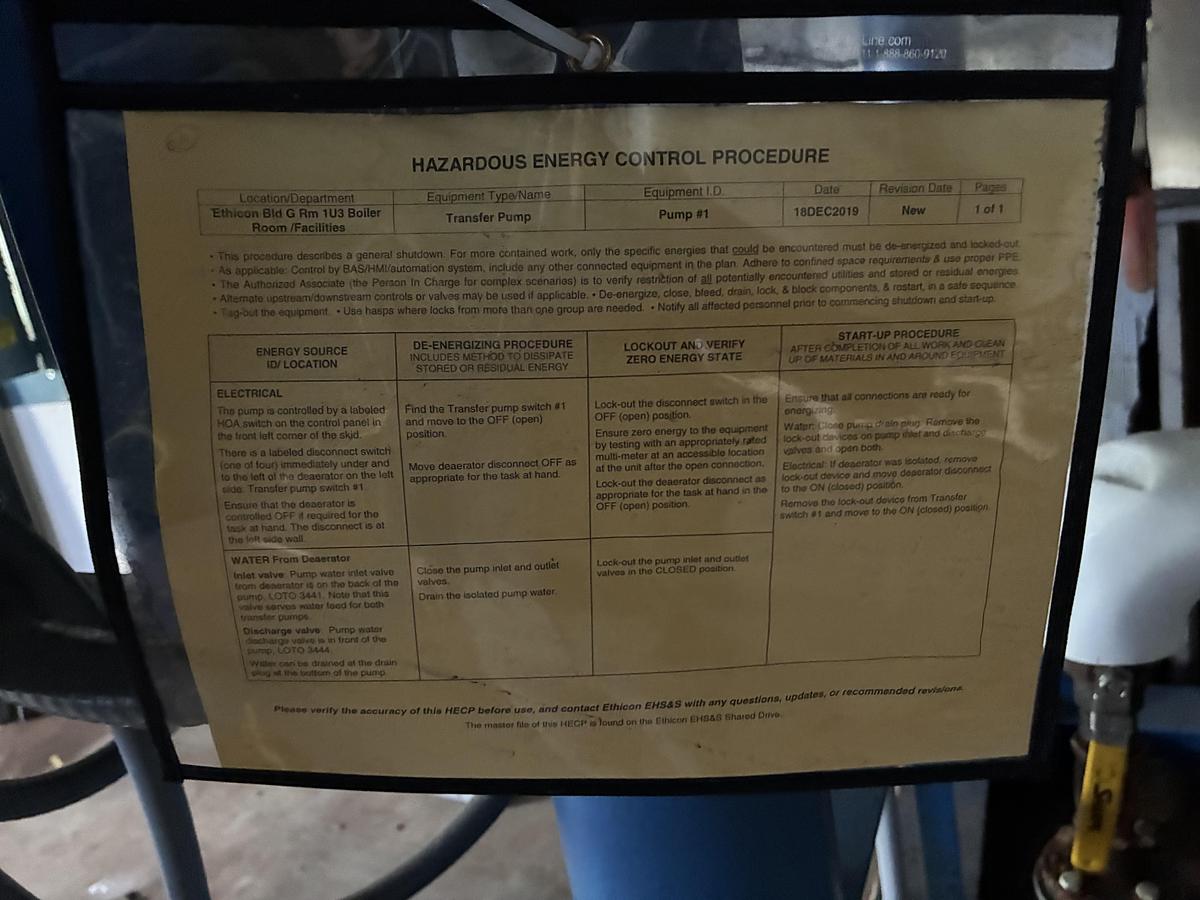

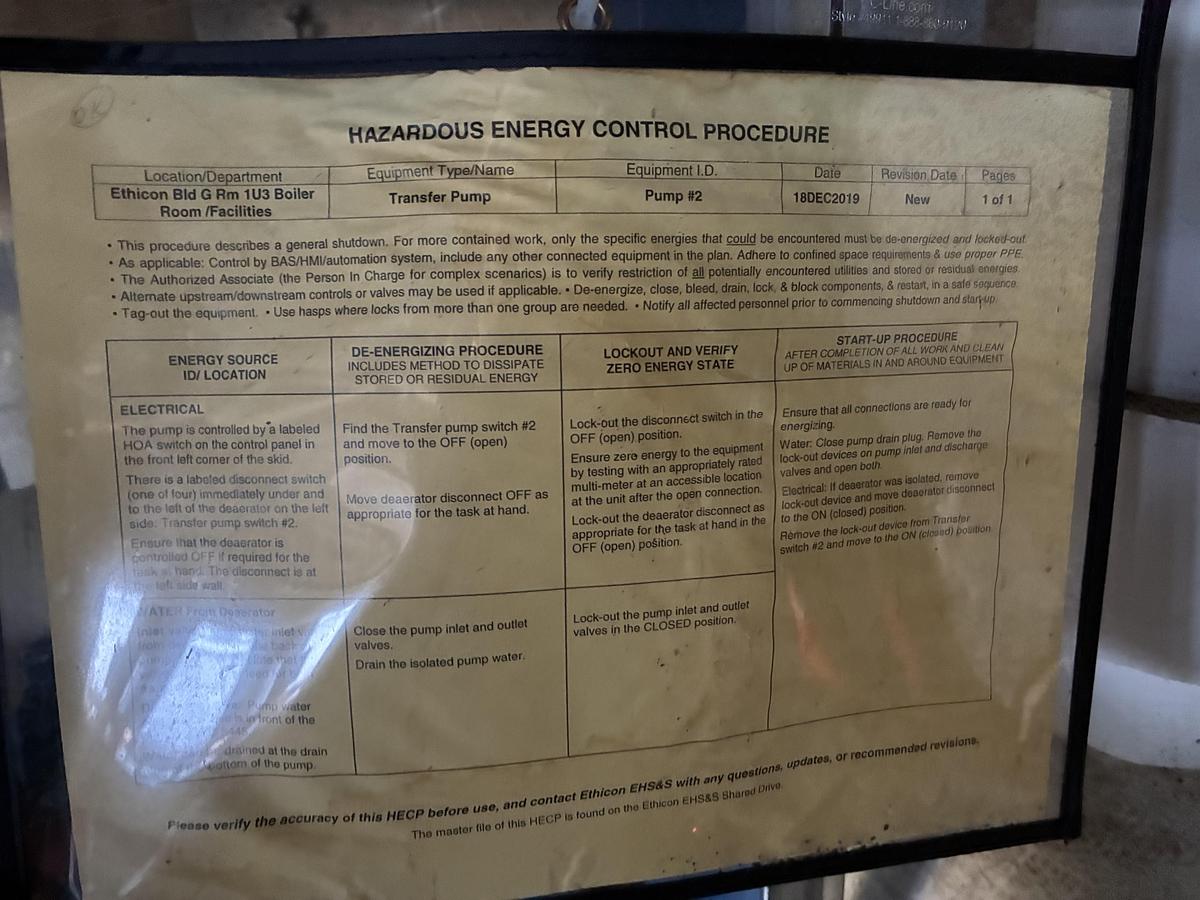

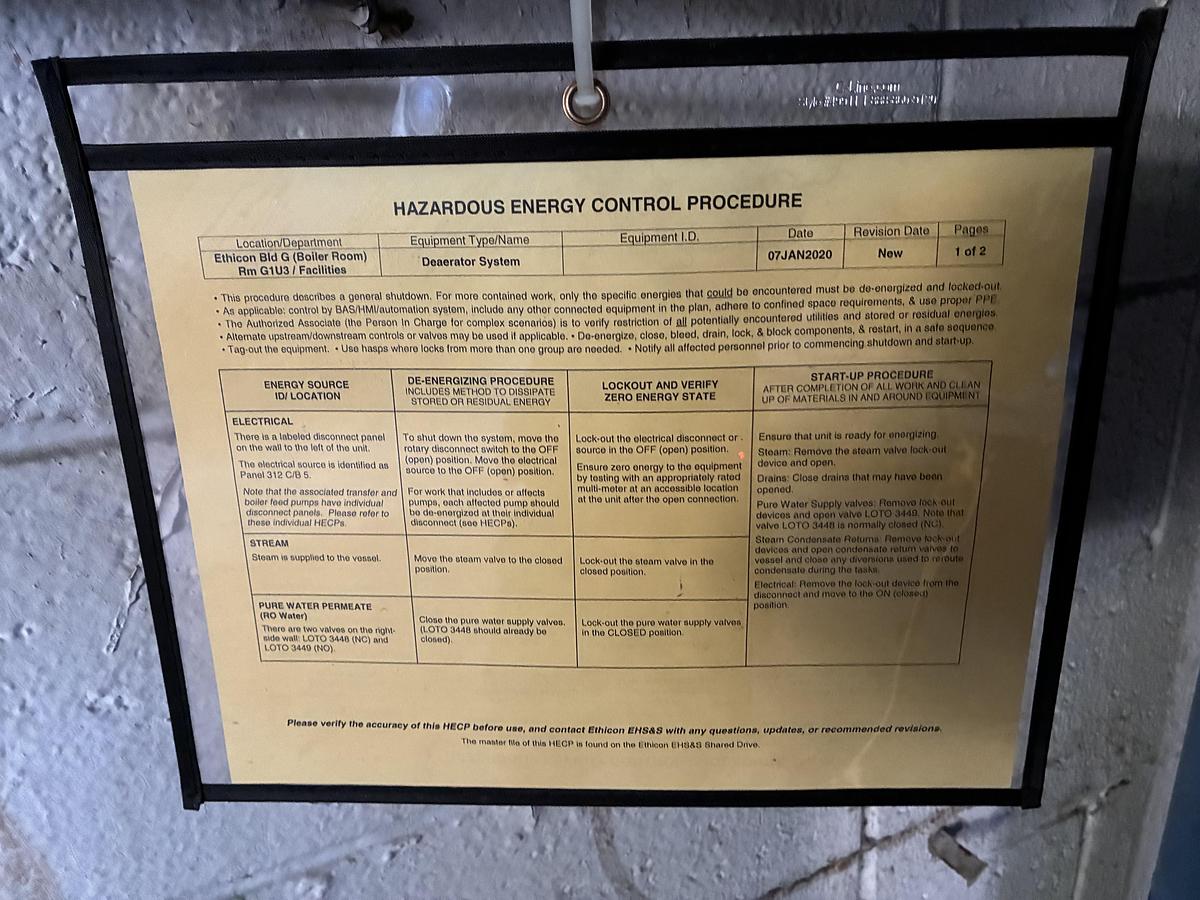

- Hazardous Energy Control Procedures (HECP)

- Lockout/tagout provisions

- Emergency shutdown systems

- Pressure relief devices

- Flame safeguard controls

- Water level protection

Technical Details

Pump Specifications

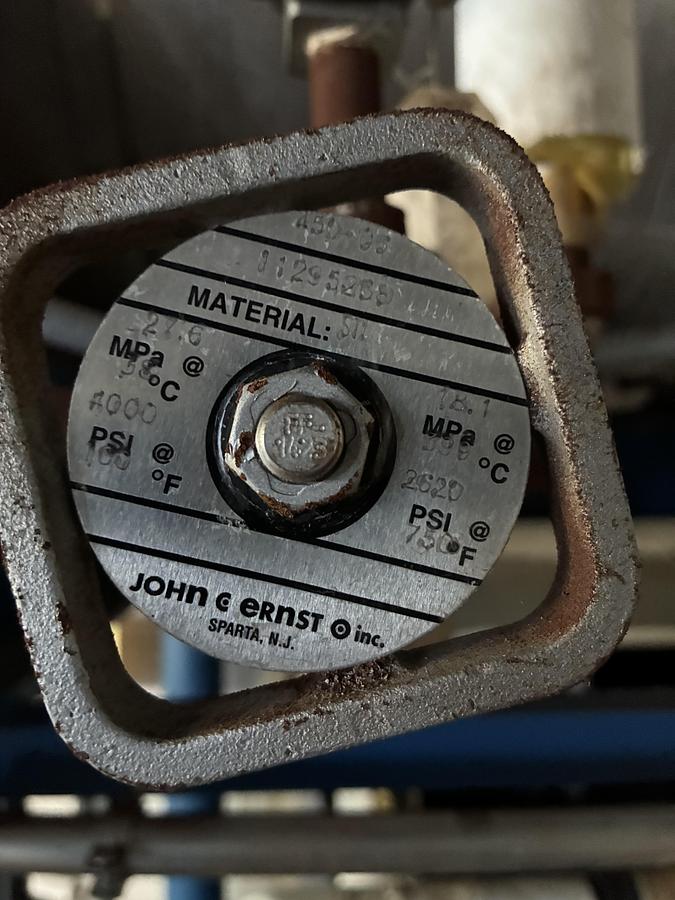

- Transfer Pumps: John G Ernst Inc.

- Location: Sparta, N.J.

- Pressure Rating: 100 PSI @ 180°F

- Temperature: 220°C maximum

- Material: SR (Stainless/Resilient)

- Service: Continuous duty

Control Components

- Allen-Bradley industrial controls

- Square D electrical components

- NEMA rated enclosures

- Industrial communication protocols

- Redundant control paths

- Fail-safe operation modes

Maintenance Requirements

Routine Service

- Water treatment chemical checks

- VFD parameter verification

- Control calibration

- Valve operation testing

- Safety device testing

- Annual professional inspection

Documentation

- Hazardous Energy Control Procedures

- Equipment identification tags

- Operating procedures posted

- Maintenance schedules

- Emergency contact information

- System drawings available

Safety & Compliance

Code Compliance

- ASME Boiler Code

- NEC Electrical Code

- NFPA Standards

- OSHA Requirements

- Local Codes

- Insurance Requirements

Safety Systems

- Multiple pressure reliefs

- Low water cutoffs

- Flame safeguard systems

- Emergency stops

- Interlock systems

- Alarm annunciation

Package Includes

✓ Two (2) Altair industrial boilers

✓ AECO water treatment system

✓ Allen-Bradley control system

✓ CentriPro Aquavar VFDs

✓ Complete pump packages

✓ Professional installation

✓ Control panel integration

✓ Safety documentation

✓ Operating procedures

✓ Training materials

Service Support

Factory Support

- Altair technical services

- AECO water treatment support

- Allen-Bradley controls support

- Local certified contractors

- Emergency service available

- Preventive maintenance programs

System Integration

- Building automation compatible

- Remote monitoring capable

- Trending and data logging

- Alarm management systems

- Energy management interface

- Predictive maintenance ready

Specifications

| Manufacturer | Altair |

| Condition | Used |

| Stock Number | Site 2- Room 3- #1 |