Industrial VFD-Controlled Pump System with Dual Danfoss Drives

No longer available

Industrial VFD-Controlled Pump System with Dual Danfoss Drives

Location:Ohio

Description

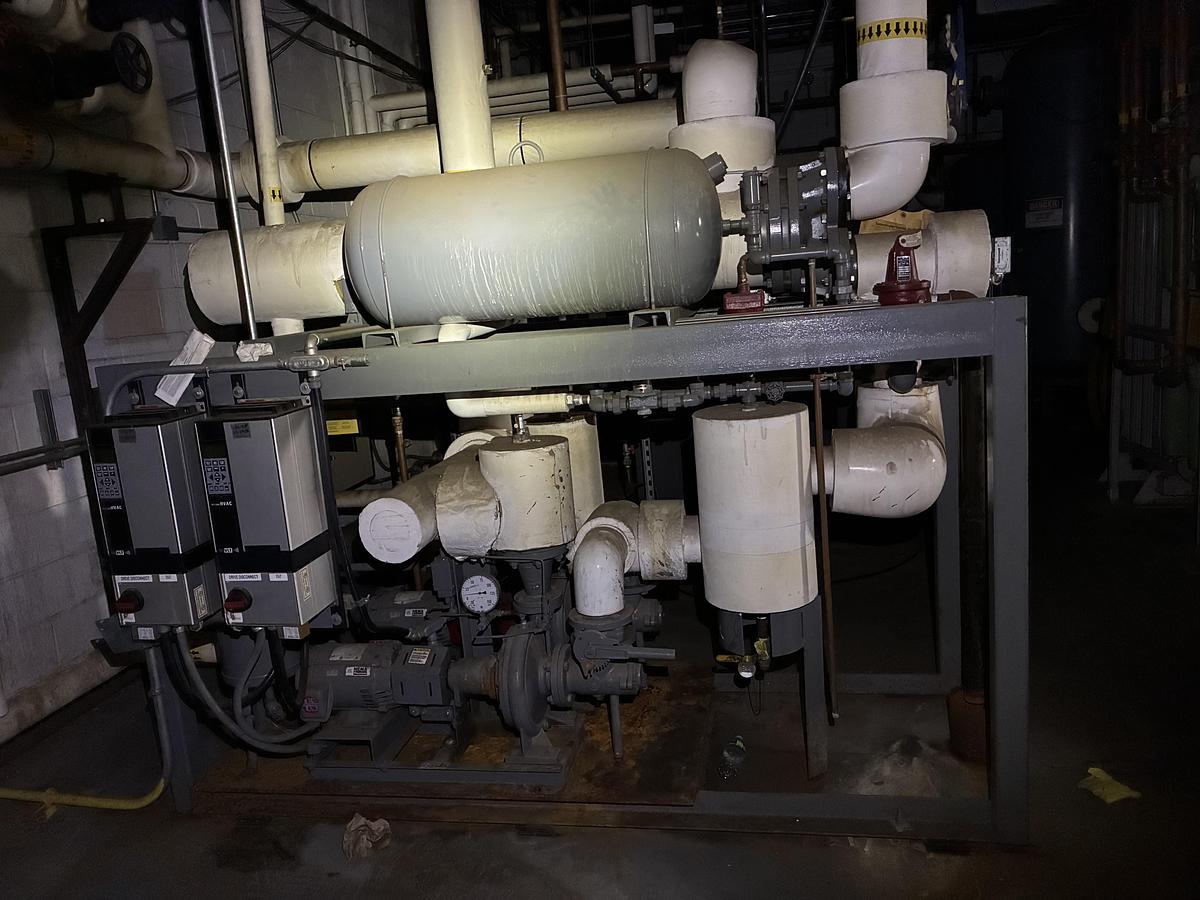

Overview

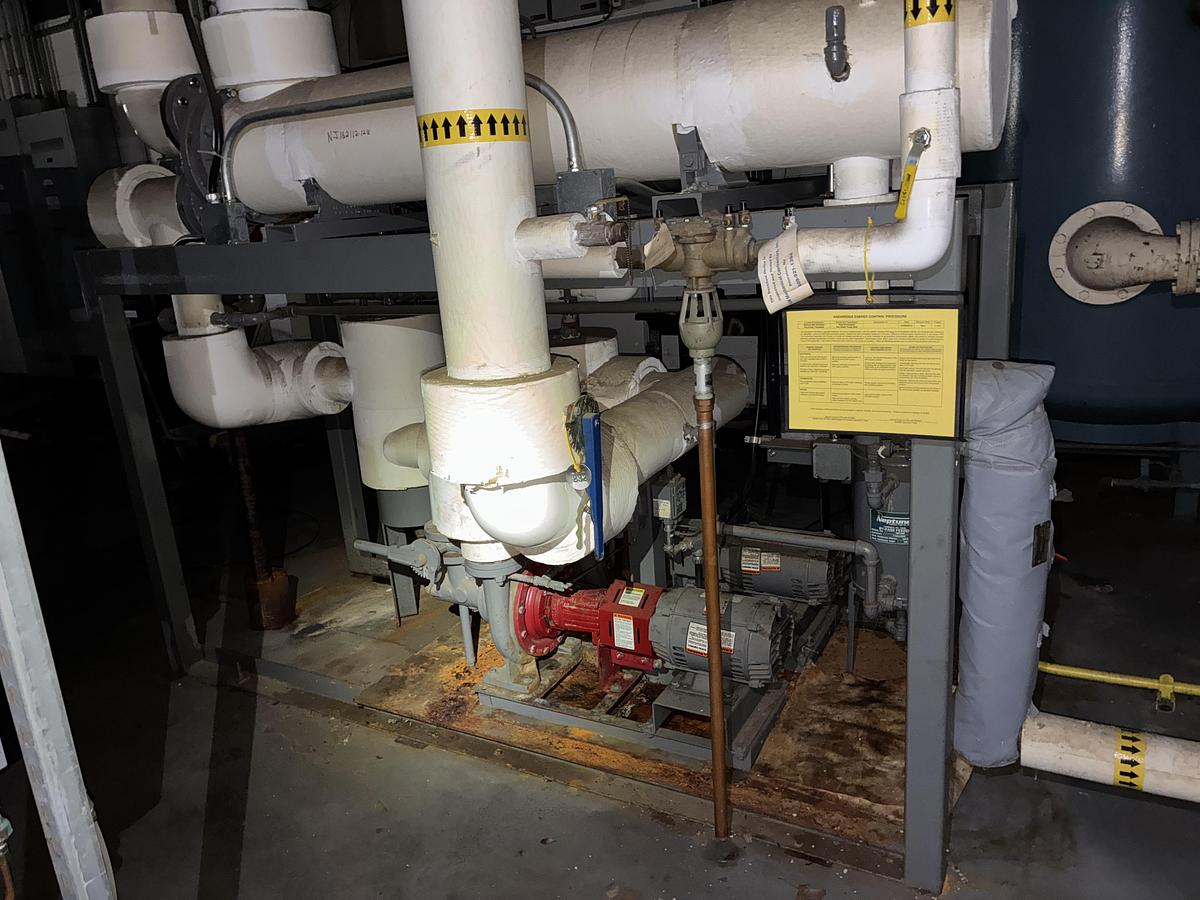

This Professional Industrial Pump System features dual Danfoss VLT 6000 HVAC Variable Frequency Drives controlling high-capacity pumps for critical HVAC applications. The system includes complete motor control, safety disconnects, pressure monitoring, and professional piping assembly. With redundant VFD control and heavy-duty pump construction, this system ensures reliable, energy-efficient operation for commercial and industrial water circulation applications.

Design and Performance

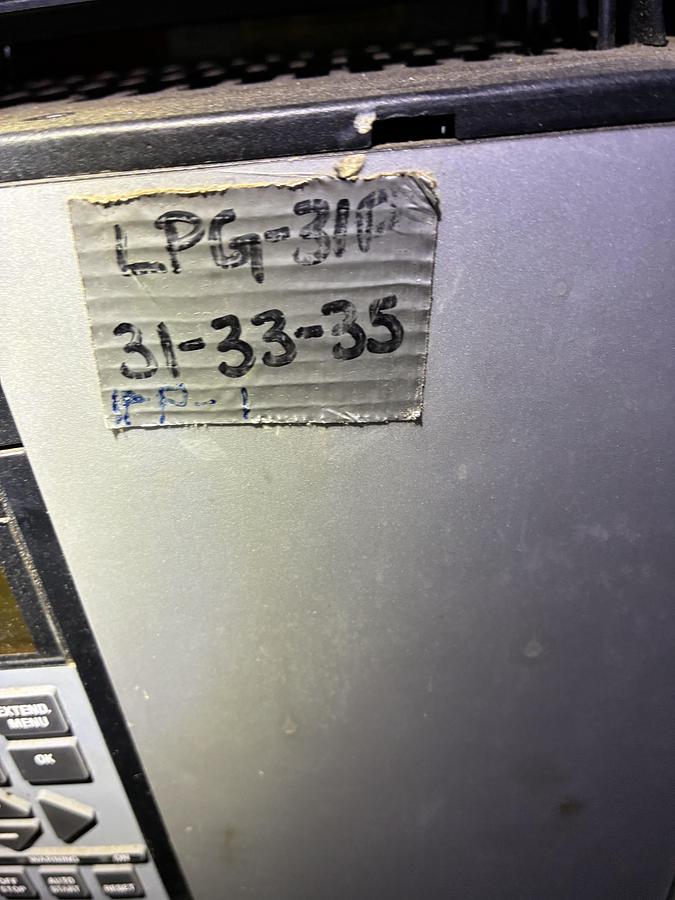

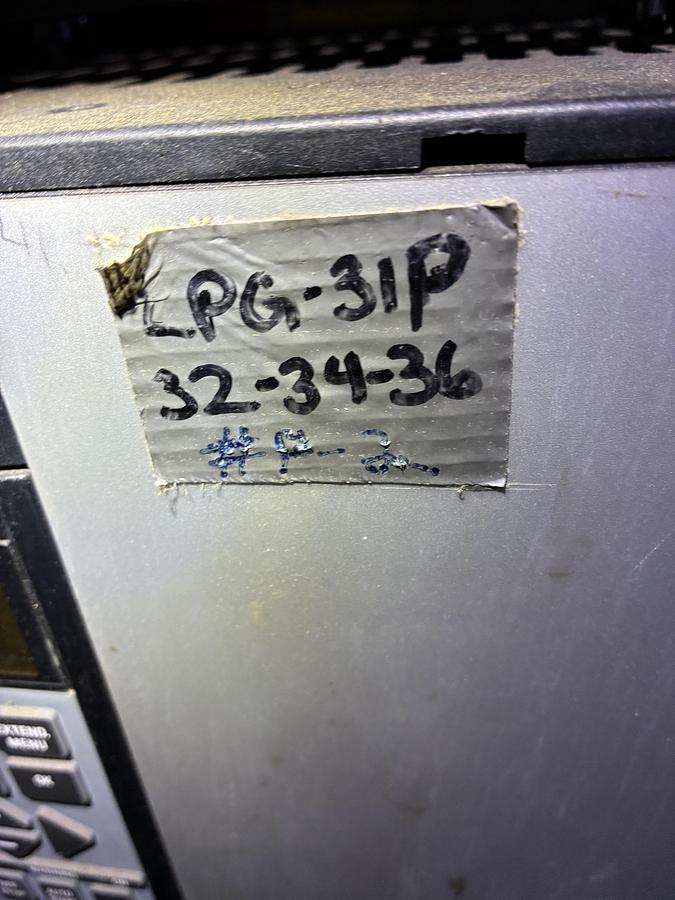

VFD Control System

- Manufacturer: Danfoss

- Model: VLT 6000 HVAC Series

- Quantity: Two (2) VFD units

- Application: HVAC-specific programming

- Interface: Digital display with keypad

- Configuration: Lead/lag capability

- Disconnect: Individual safety disconnects

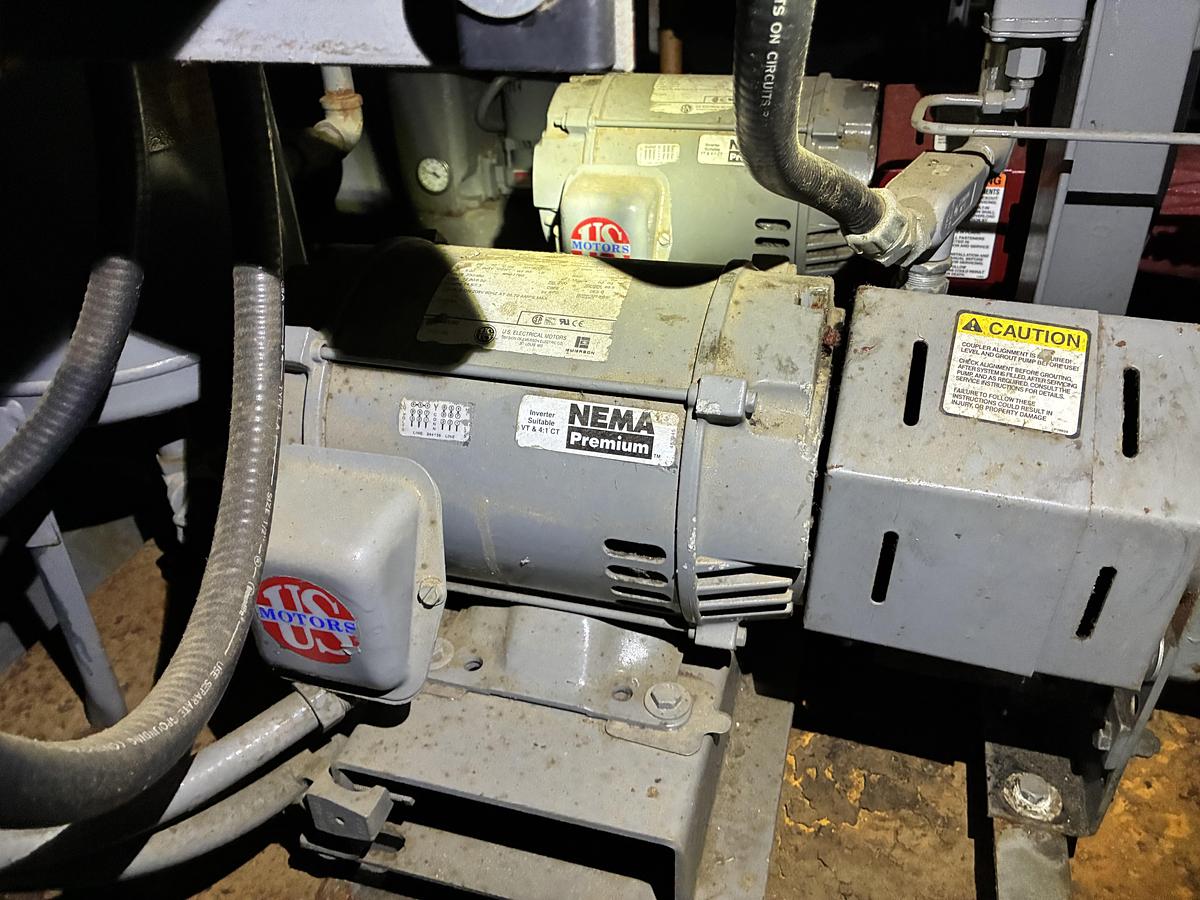

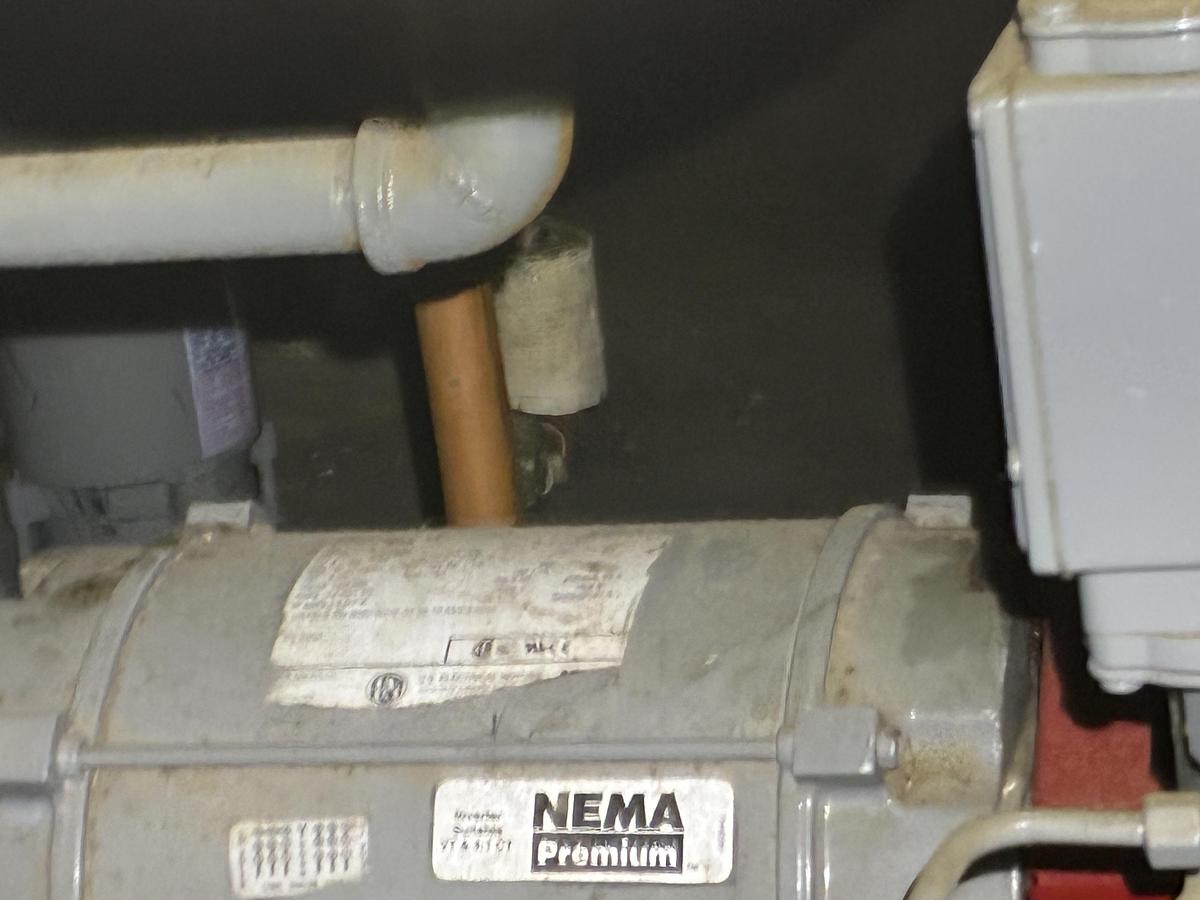

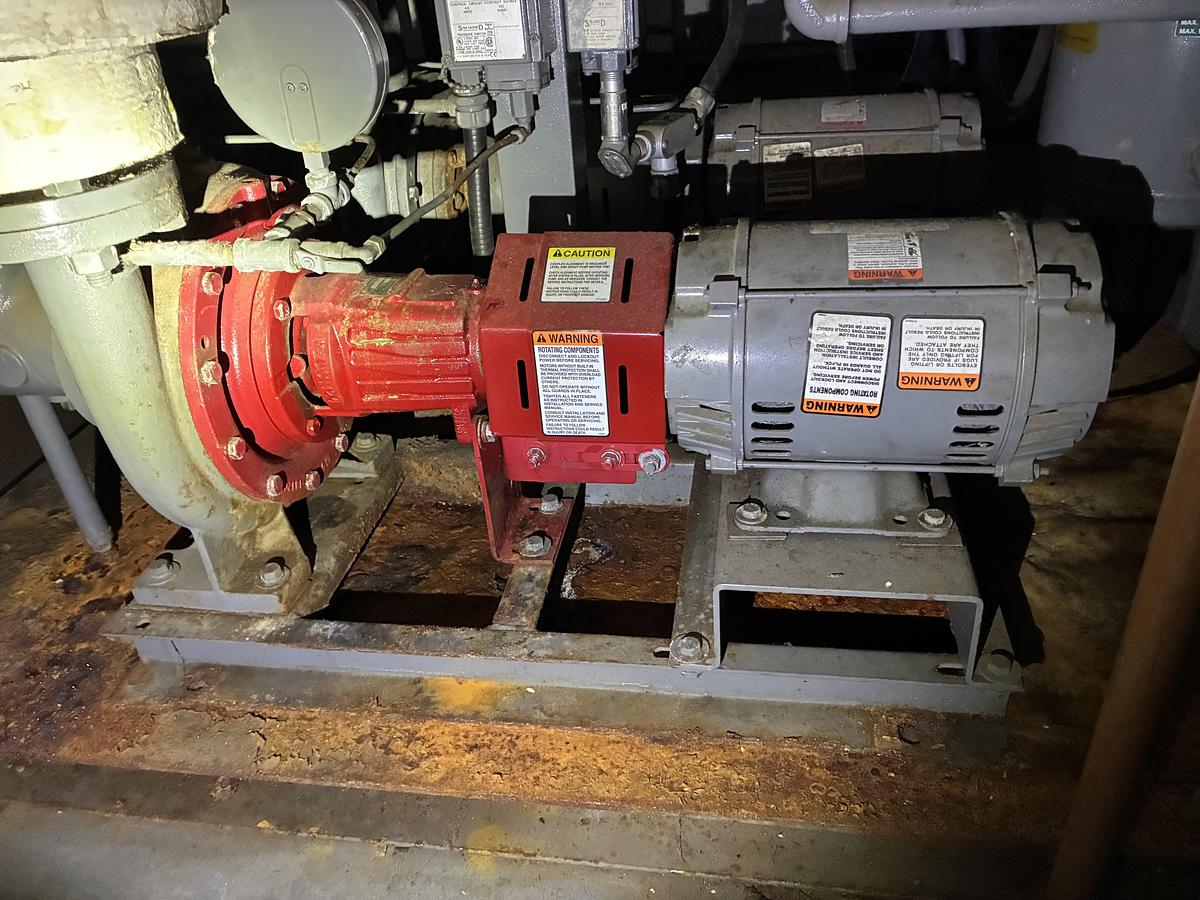

Motor Specifications

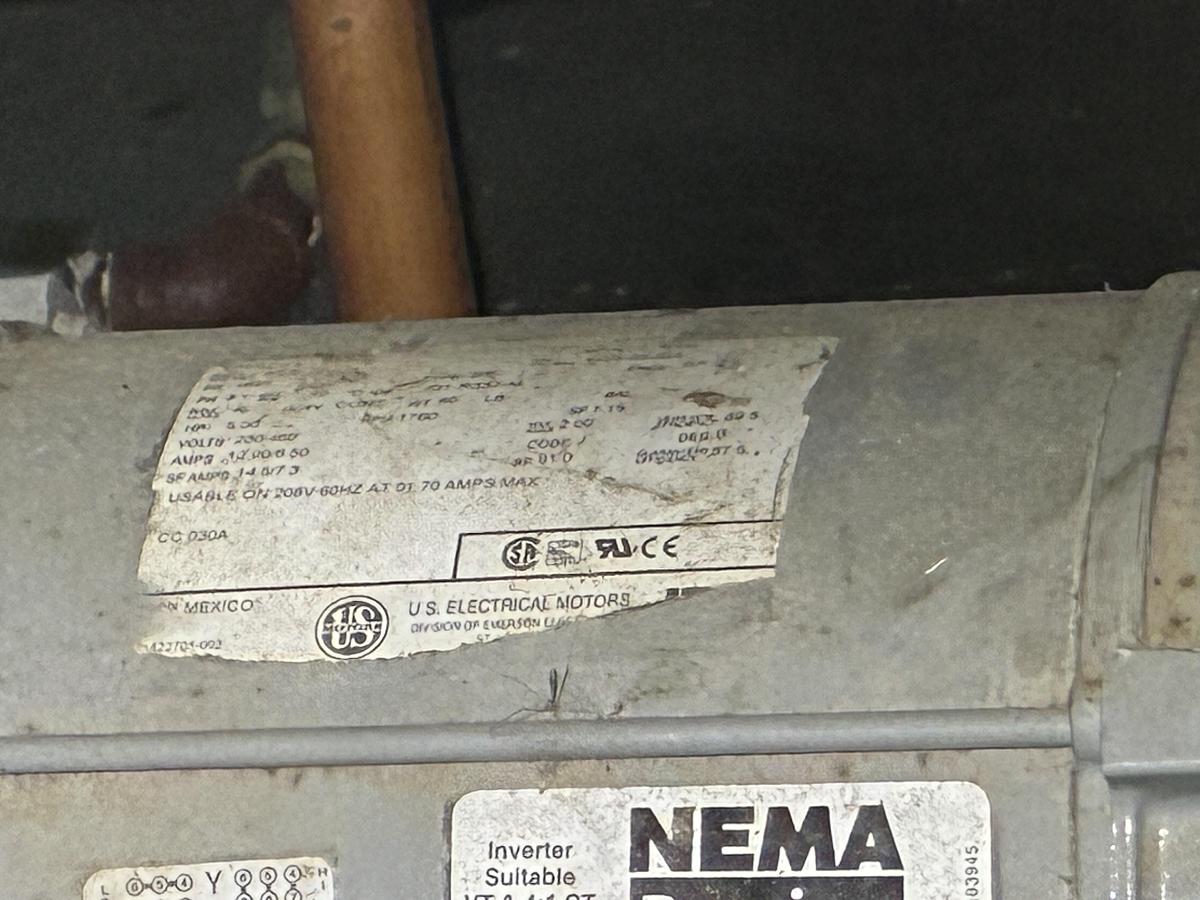

- Manufacturer: U.S. Electrical Motors

- Power: Multi-HP capacity

- Voltage: 208-230/460V

- Type: NEMA Premium Efficiency

- Inverter Suitable: Yes

- Service Factor: 1.15

- Enclosure: TEFC

Complete System Package

Main Components

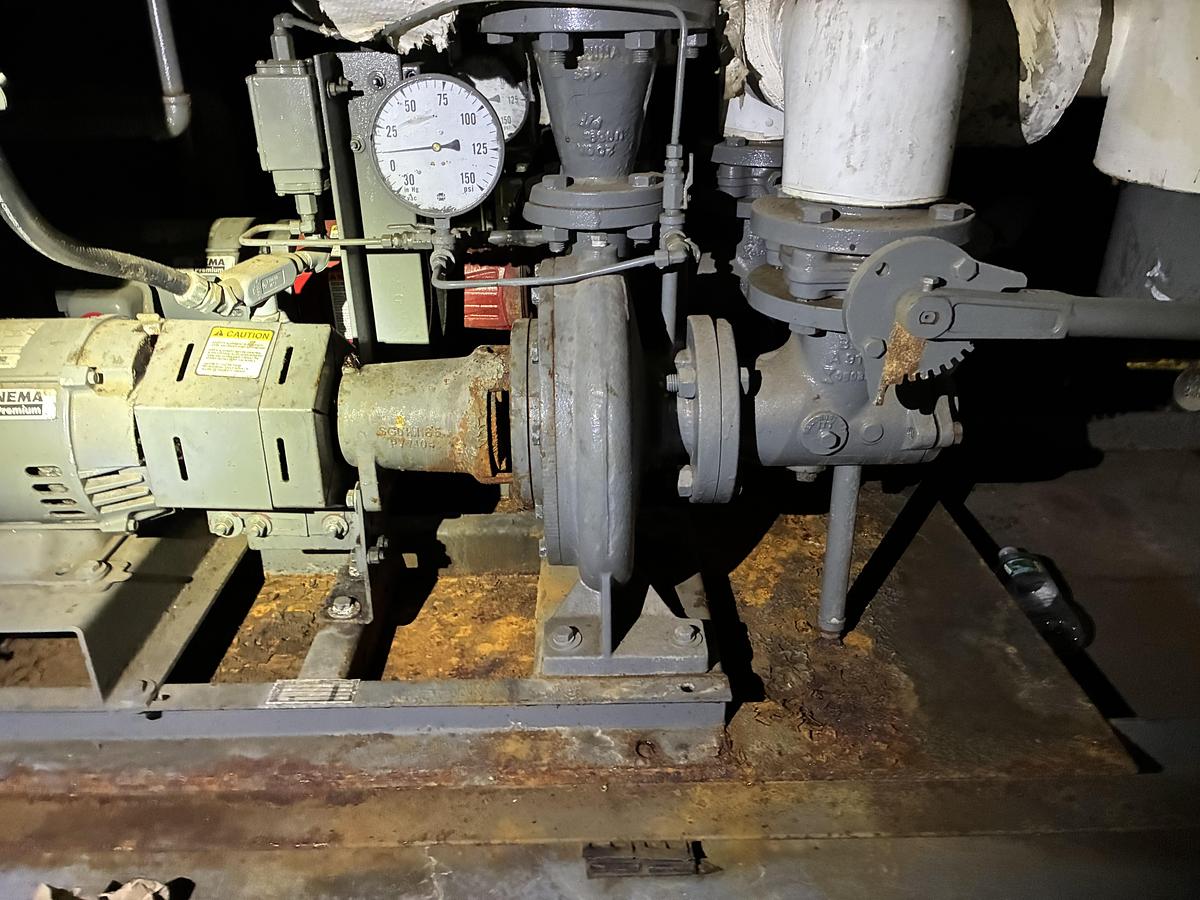

- Two (2) industrial centrifugal pumps

- Two (2) Danfoss VLT 6000 HVAC VFDs

- Complete motor control panel

- Safety disconnect switches

- Pressure gauge (0-150 PSI)

- ASME relief valve (30 PSI set)

- Professional piping assembly

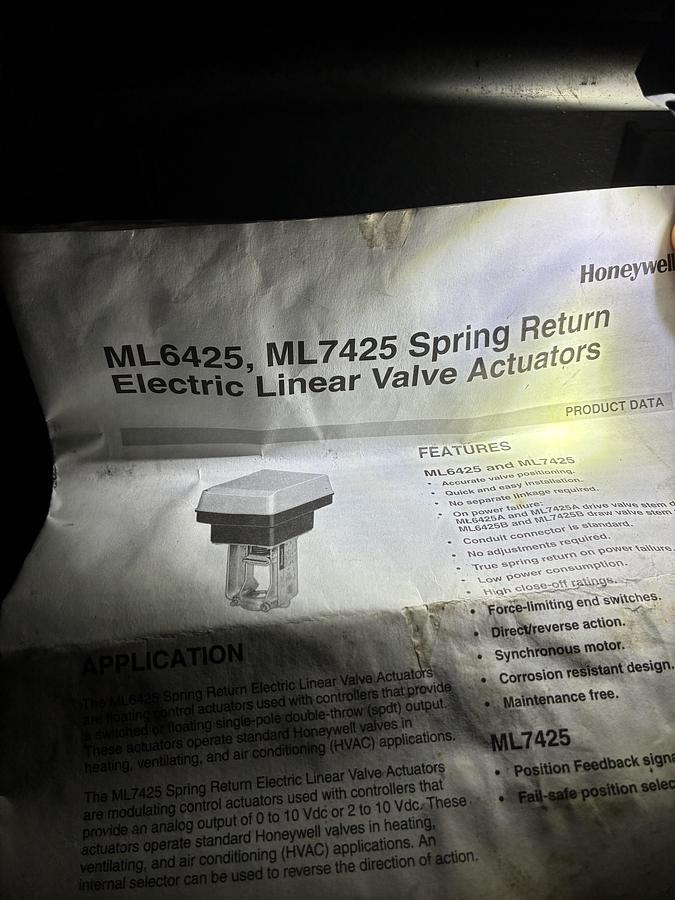

- Honeywell valve actuators

- Complete mounting framework

Control Features

- VFD Benefits: Variable speed control

- Energy Savings: Optimized pump operation

- Soft Start: Reduced mechanical stress

- Monitoring: Real-time performance data

- Protection: Built-in motor protection

- Communication: BACnet/Modbus capable

Key Specifications

Pump Details

- Type: End suction centrifugal

- Configuration: Dual pump system

- Pressure Rating: 150 PSI system

- Relief Valve: 30 PSI ASME certified

- Capacity: 3,300,000 BTU/HR

- Connection: Flanged inlet/outlet

VFD Specifications

- Series: VLT 6000 HVAC

- Control: Closed-loop PID

- Display: LCD with multi-language

- Programming: HVAC-optimized

- Protection: IP20 enclosure

- Compliance: UL/CSA certified

System Features

Advanced Control

- Variable speed operation

- Automatic lead/lag alternation

- Pressure-based control

- Flow optimization

- Energy monitoring

- Fault diagnostics

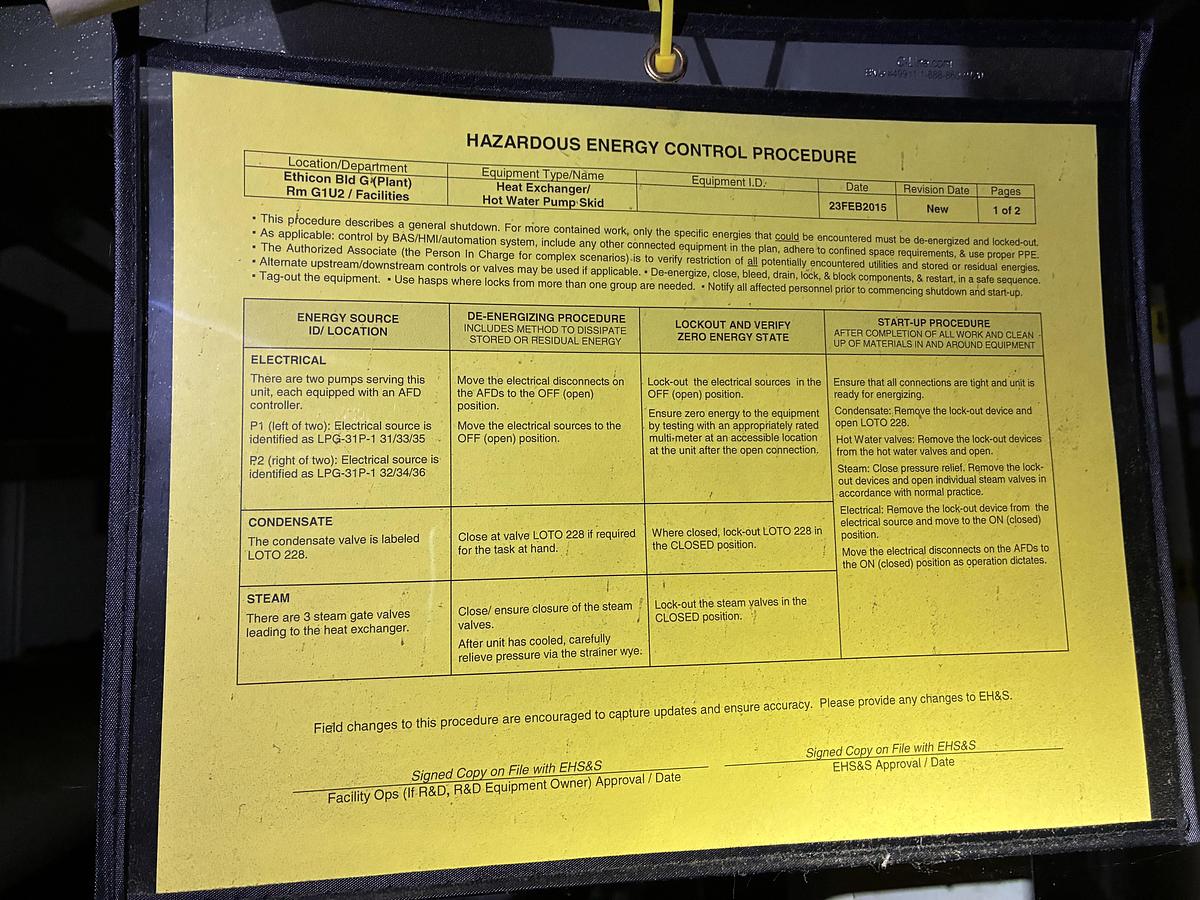

Safety Systems

- Individual disconnects with lockout

- ASME relief valve protection

- Emergency stop capability

- Overload protection

- Phase loss protection

- Dry run protection

Automation Integration

- Actuators: Honeywell ML6425/ML7425

- Control: 0-10 VDC or 2-10 VDC

- Feedback: Position feedback available

- Spring Return: Yes

- Torque: 35 lb-in (ML6425), 70 lb-in (ML7425)

Ideal Applications

- Commercial HVAC Systems

- Chilled Water Plants

- Condenser Water Systems

- Campus Distribution

- High-Rise Buildings

- Industrial Process Cooling

- Data Center Cooling

- Hospital Critical Systems

- Variable Flow Systems

- Energy-Efficient Retrofits

Technical Advantages

VFD Benefits

- Energy Savings: Up to 50% reduction

- Soft Starting: Eliminates water hammer

- Speed Control: Matches system demand

- Extended Life: Reduced mechanical wear

- Diagnostics: Built-in troubleshooting

- Communication: Building automation ready

System Benefits

- Redundant pump configuration

- Individual pump control

- Automatic backup operation

- Pressure-based optimization

- Remote monitoring capability

- Maintenance mode operation

Installation Requirements

- Three-phase electrical supply

- Adequate ventilation for VFDs

- EMC-compliant wiring practices

- Proper grounding system

- Line reactors if required

- Control wiring separation

- BMS integration planning

Control Capabilities

VFD Functions

- PID control loops

- Sleep mode function

- Cascade pump control

- Constant pressure mode

- Flow compensation

- Schedule operation

- Alarm management

Monitoring Features

- Real-time speed display

- Power consumption

- Operating hours

- Fault history

- Pressure monitoring

- Temperature monitoring

- Maintenance alerts

Safety & Compliance

- VFDs: UL Listed

- Relief Valve: ASME Section VIII

- Motors: NEMA Premium Efficiency

- Installation: NEC compliant

- Disconnects: Lockout/tagout capable

- System: Industrial safety standards

Package Includes

✓ Two (2) industrial pumps

✓ Two (2) Danfoss VLT 6000 HVAC VFDs

✓ Control panel with disconnects

✓ Pressure gauge (0-150 PSI)

✓ ASME relief valve (30 PSI)

✓ Honeywell valve actuators

✓ Professional piping assembly

✓ Mounting framework

✓ System identification tags

Component Details

Bell & Gossett Components

- Triple Duty Valve: Combination shut-off, check, and balancing

- Relief Valve: Model 3301, 30 PSI set point

- Capacity: 3,300,000 BTU/HR

- Inlet: 1-1/2 inch

- Certification: ASME/HV rated

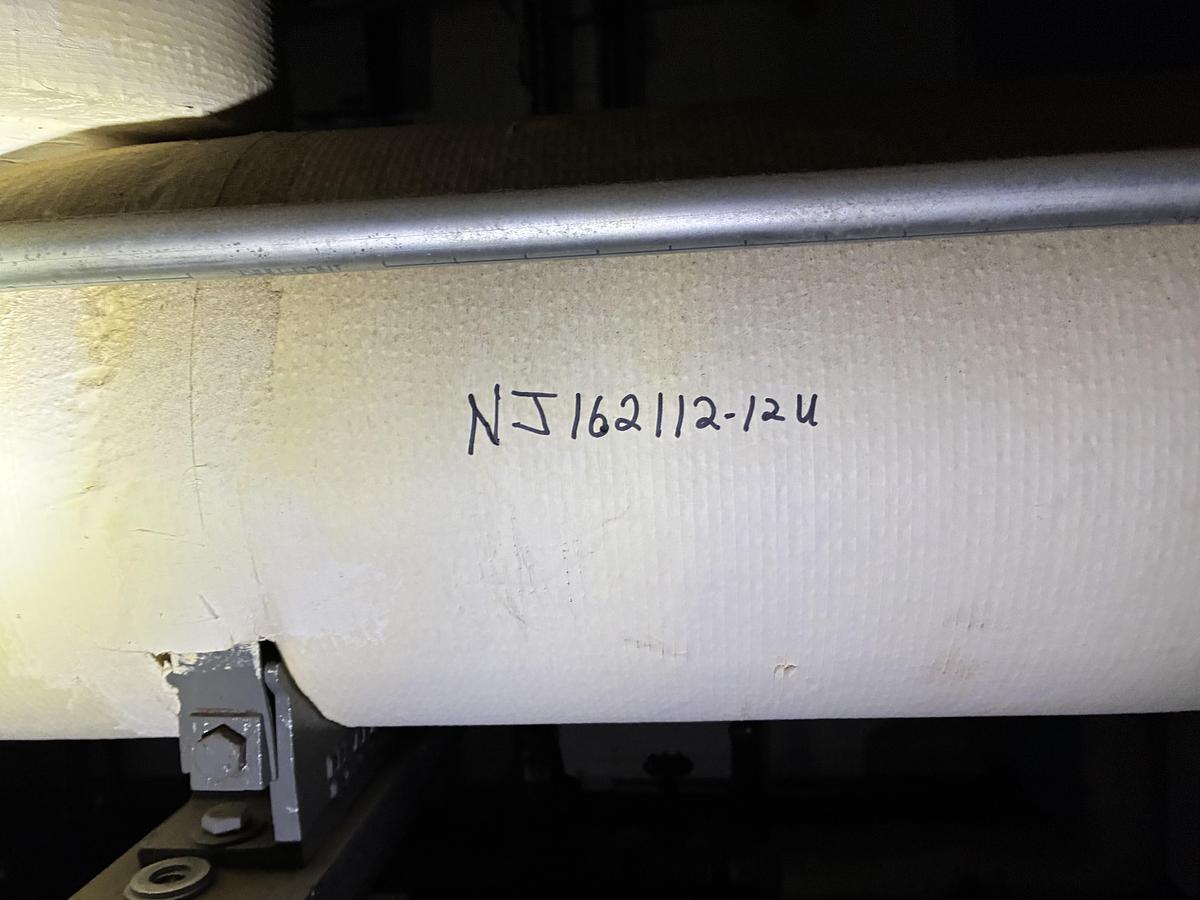

System Identification

- Tag: NJ162112-12U

- Location: Mechanical room installation

- Configuration: Parallel pump arrangement

Energy Efficiency

- VFD control reduces energy consumption

- Matches pump speed to system demand

- Eliminates throttling losses

- Reduces peak demand charges

- Extends equipment life

- ROI typically 1-3 years

Maintenance Features

- Front-access VFD panels

- Individual pump isolation

- Diagnostic displays

- Runtime balancing

- Predictive maintenance alerts

- Easy filter access

- Standard replacement parts

Specifications

| Model | VLT 6000 HVAC Series |

| Condition | Used |

| Stock Number | Site 2- Room 1- #7 |