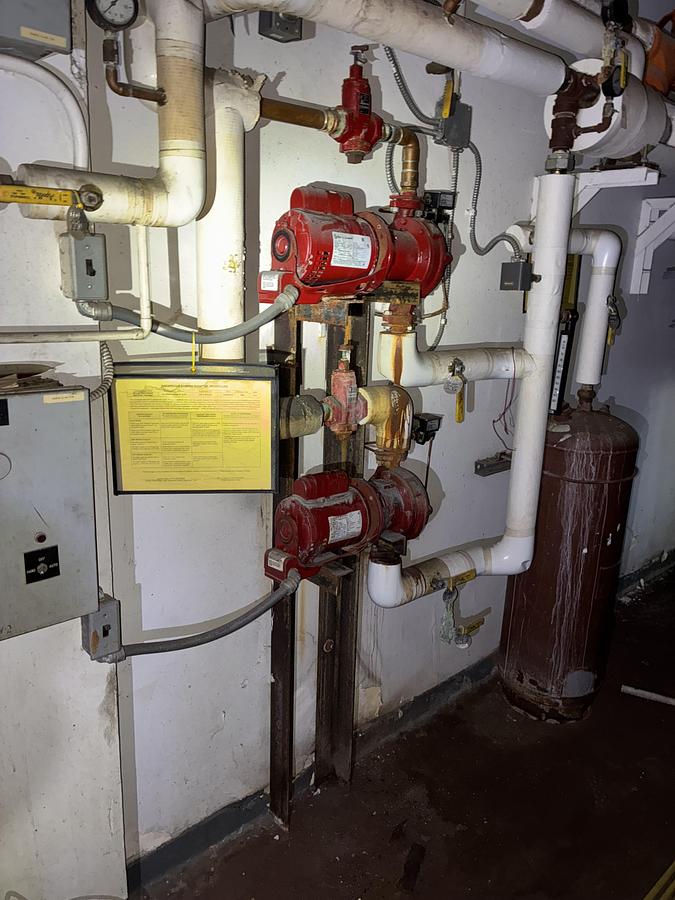

Bell & Gossett Dual Hot Water Pump System (P1 & P2)

Bell & Gossett Dual Hot Water Pump System (P1 & P2)

Contact us for price

Location:Ohio

Description

Overview

This Bell & Gossett Dual Hot Water Pump System features a lead/lag configuration with two professionally installed centrifugal pumps designed for commercial hot water circulation. Each pump is equipped with 1/4-1/6 HP motors operating at 115/208-230V, providing reliable hot water distribution with automatic backup capability. The system includes GE 300-Line Control panels, complete piping assembly, and professional installation suitable for hotels, hospitals, apartment buildings, and other commercial facilities requiring dependable hot water circulation.

Design and Performance

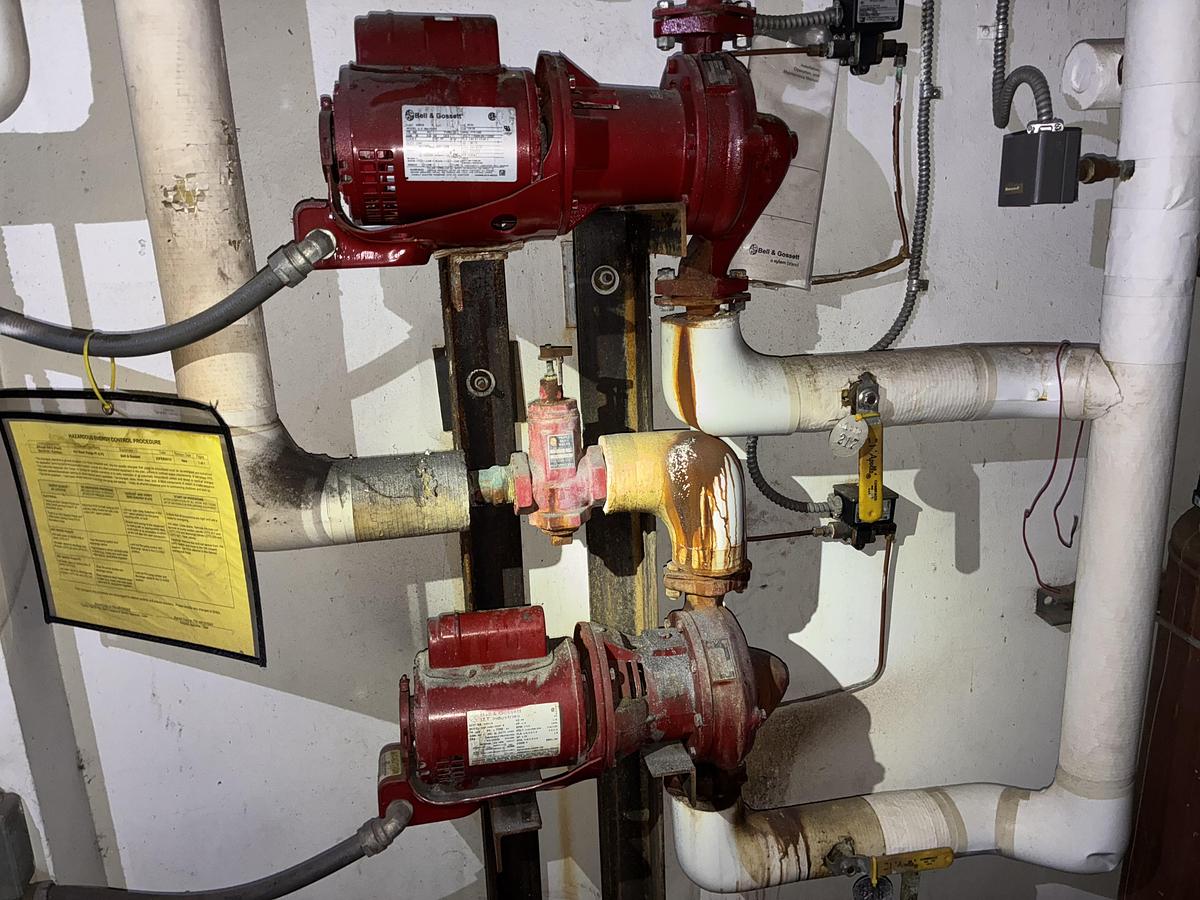

Motor Specifications (Per Pump)

- Manufacturer: Bell & Gossett

- Model: Q D 56A17D57F

- Motor HP: 1/4-1/6 HP

- Voltage: 115/208-230-110/220V

- Amperage: 2.8/1.5-1.4-2.4/1.2 FLA

- Speed: 1715-1440 RPM

- Phase: Single Phase

- Frequency: 60-50 Hz

- Service Factor: 1.35-1.0

- Frame: 56

- Enclosure: DP (Drip Proof)

Complete System Package

Main Components

- Two (2) Bell & Gossett centrifugal pumps

- Two (2) GE 300-Line Control panels

- Complete piping manifold

- Isolation valves (each pump)

- Check valves on discharge

- Pressure gauge assembly

- Professional copper piping

- Mounting framework

- Electrical connections

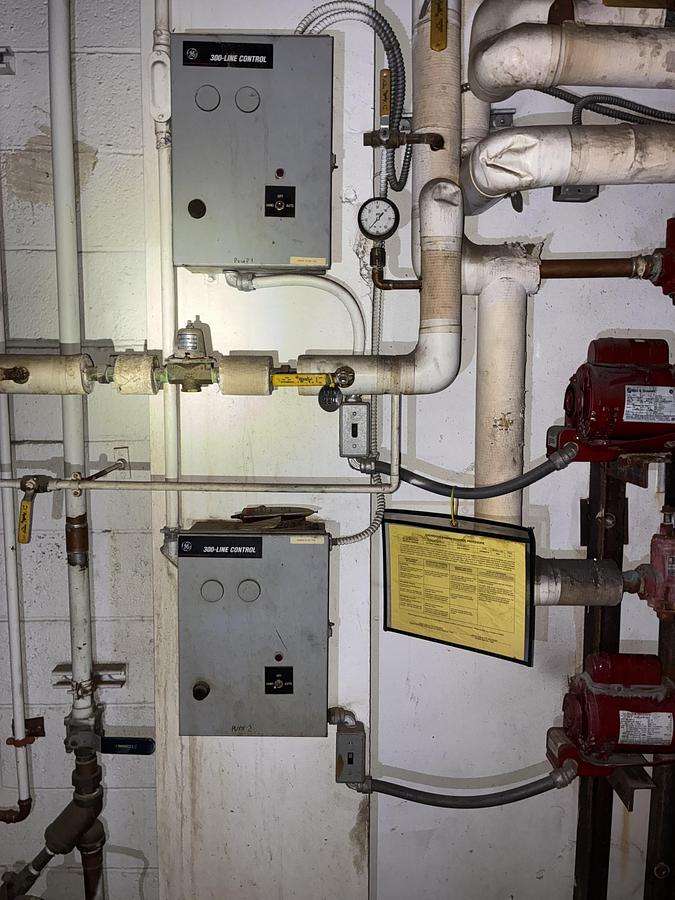

Control System

- Control Panels: GE 300-Line Control (2 units)

- Configuration: Lead/lag operation

- Switching: Manual selector switches

- Protection: Motor overload protection

- Operation: Automatic alternation capability

- Indicators: Run status lights

Key Features

Pump Configuration

- Type: Close-coupled centrifugal

- Arrangement: Parallel pumps (P1 & P2)

- Operation: Lead/lag with backup

- Flow Path: Common suction/discharge

- Redundancy: 100% backup capability

- Service: Individual pump isolation

System Benefits

- Continuous hot water circulation

- Automatic backup operation

- Energy-efficient motors

- Quiet operation

- Minimal maintenance

- Long service life

- Professional installation

System Specifications

Hydraulic Performance

- Design: Hot water service

- Temperature: Up to 230°F

- Pressure: System dependent

- Flow Rate: Based on system requirements

- Head: Per pump curve

- Efficiency: Optimized impeller design

Electrical Details

- Power Options: 115V or 208-230V

- Protection: Thermally protected

- Starting: Direct on line

- Control Voltage: 115V typical

- Wiring: NEC compliant

- Grounding: Per code

Ideal Applications

- Hotels & Hospitality

- Hospitals & Healthcare

- Multi-family Residential

- Office Buildings

- Schools & Universities

- Industrial Facilities

- Commercial Kitchens

- Fitness Centers

- Any facility requiring reliable hot water

Installation Features

Piping Configuration

- Professional copper piping

- Flanged pump connections

- Isolation ball valves

- Check valves installed

- Common headers

- Pressure monitoring

- Service valves

Control Integration

- Wall-mounted control panels

- Easy access for service

- Clear labeling (P1 & P2)

- Manual/automatic selection

- Status indication

- Safety interlocks

Operational Advantages

Lead/Lag Benefits

- Automatic pump alternation

- Extended equipment life

- Balanced run times

- Reduced wear

- Energy optimization

- Backup protection

Maintenance Features

- Individual pump isolation

- No system shutdown required

- Easy motor access

- Standard replacement parts

- Visual operation indicators

- Documented service points

Technical Details

Motor Features

- Insulation: Class B

- Bearings: Ball bearing

- Lubrication: Permanently lubricated

- Protection: Thermal overload

- Efficiency: High efficiency design

- Duty: Continuous

Pump Construction

- Cast iron volute

- Bronze impeller

- Mechanical seal

- Stainless steel shaft

- Precision machined

- Factory balanced

Control System Details

GE 300-Line Features

- Reliable motor control

- Overload protection

- Manual override

- Status indication

- Fault detection

- Easy troubleshooting

Operation Modes

- Manual pump selection

- Automatic alternation

- Both pumps for peak demand

- Single pump operation

- Emergency override

- Service mode

Energy Efficiency

- Variable speed compatible

- High efficiency motors

- Optimized impeller design

- Reduced cycling losses

- Right-sized for application

- Lower operating costs

Safety & Compliance

- UL Listed: Motors and controls

- Code Compliance: NEC/local codes

- Safety Features: Multiple protections

- Thermal Protection: Built-in

- Electrical Safety: Proper grounding

- Mechanical Safety: Guard provisions

Maintenance Requirements

- Periodic seal inspection

- Motor lubrication (if required)

- Control calibration

- Valve operation check

- Pressure verification

- Annual professional service

Package Includes

✓ Two (2) Bell & Gossett pumps

✓ Two (2) 1/4-1/6 HP motors

✓ Two (2) GE control panels

✓ Complete piping assembly

✓ Isolation valves

✓ Check valves

✓ Pressure gauge

✓ Professional installation

✓ System labeling

Service Support

- Bell & Gossett factory support

- Replacement parts availability

- Local service network

- Technical documentation

- Pump curves available

- Warranty coverage

System Integration

- Works with building automation

- Temperature control compatible

- Remote monitoring capable

- Alarm contacts available

- Status feedback

- Energy management ready

Specifications

| Manufacturer | Bell & Gossett |

| Model | Q D 56A17D57F |

| Condition | Used |

| Stock Number | Site 2- Room 1- #10 |